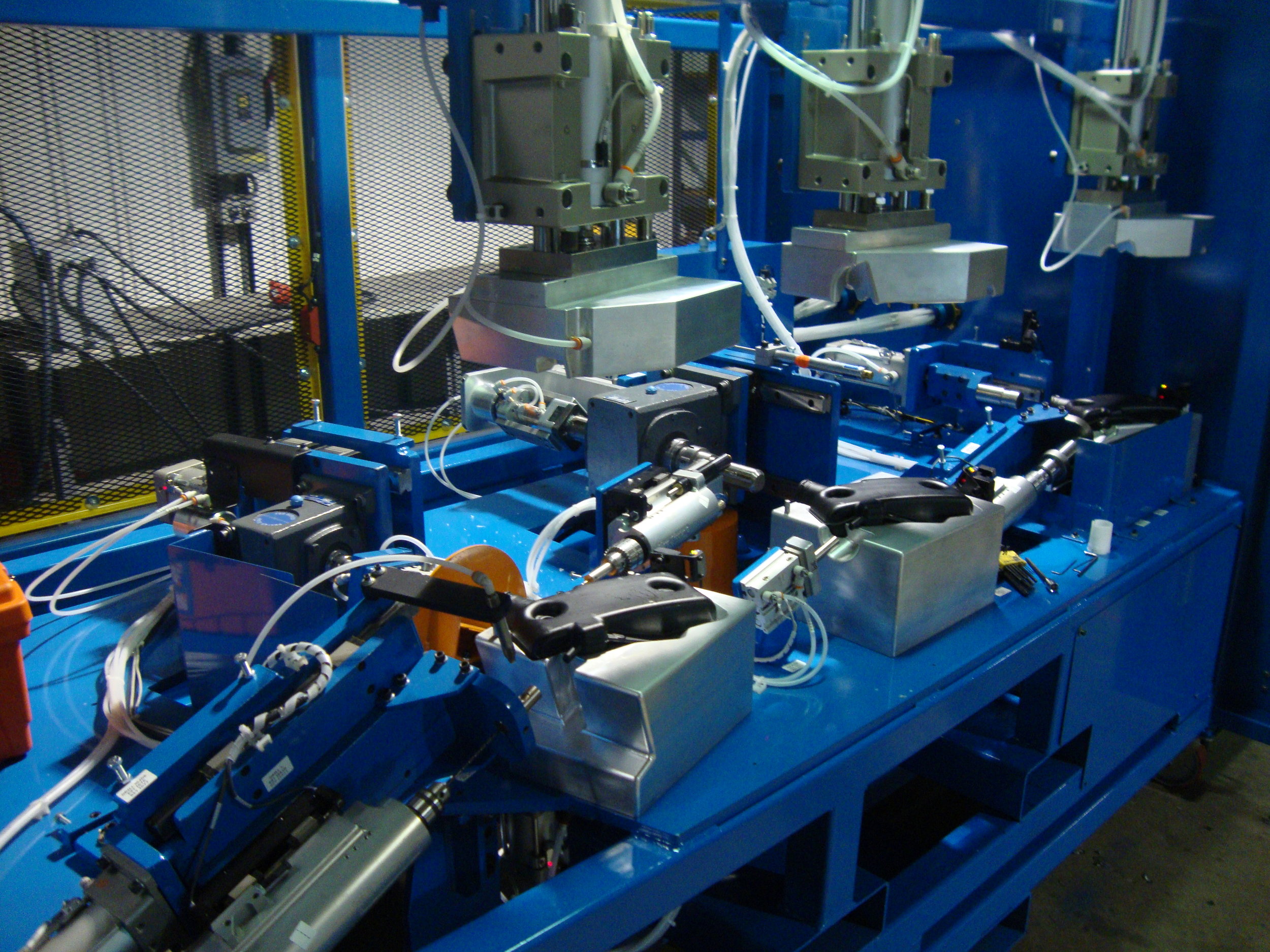

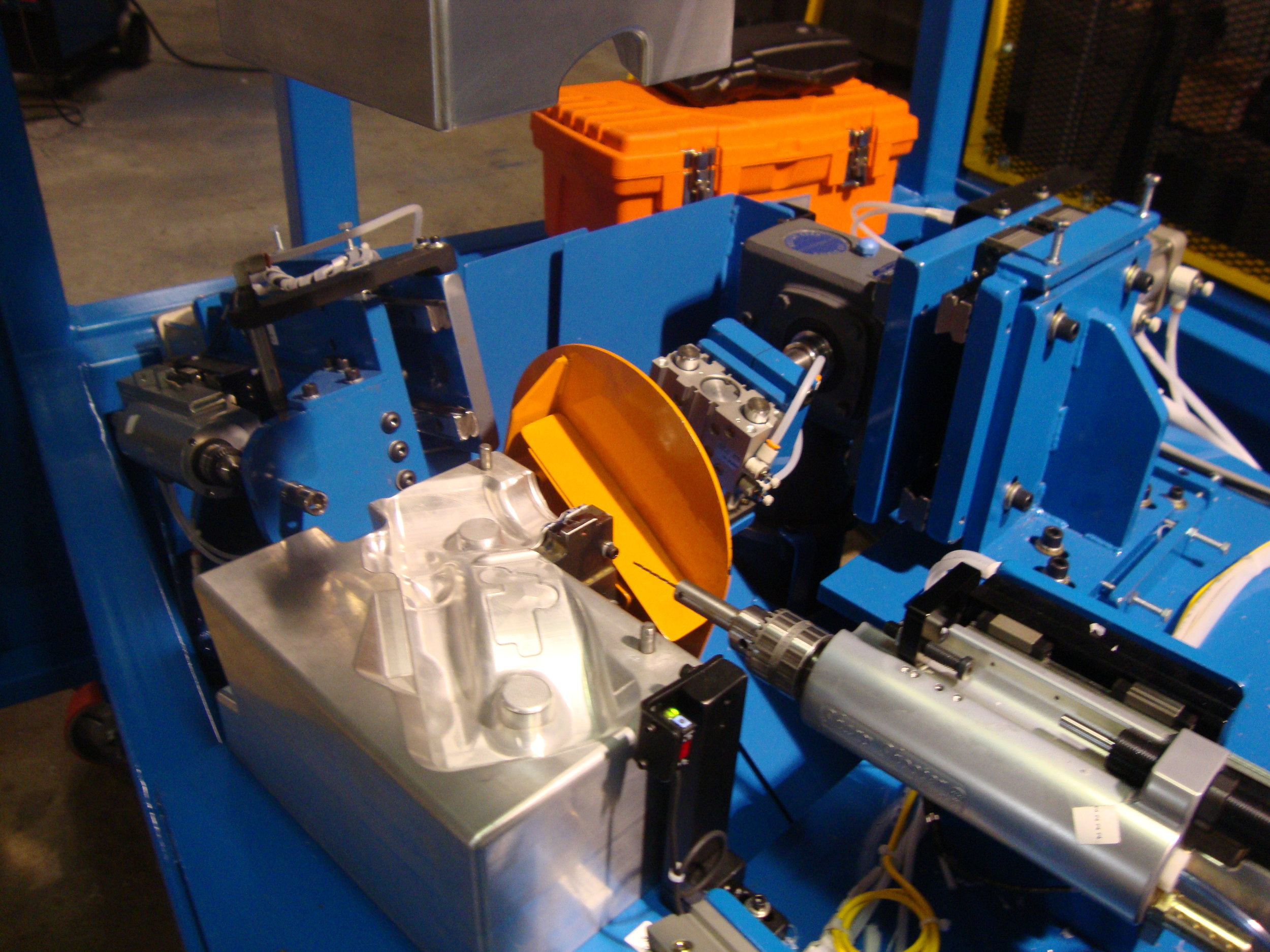

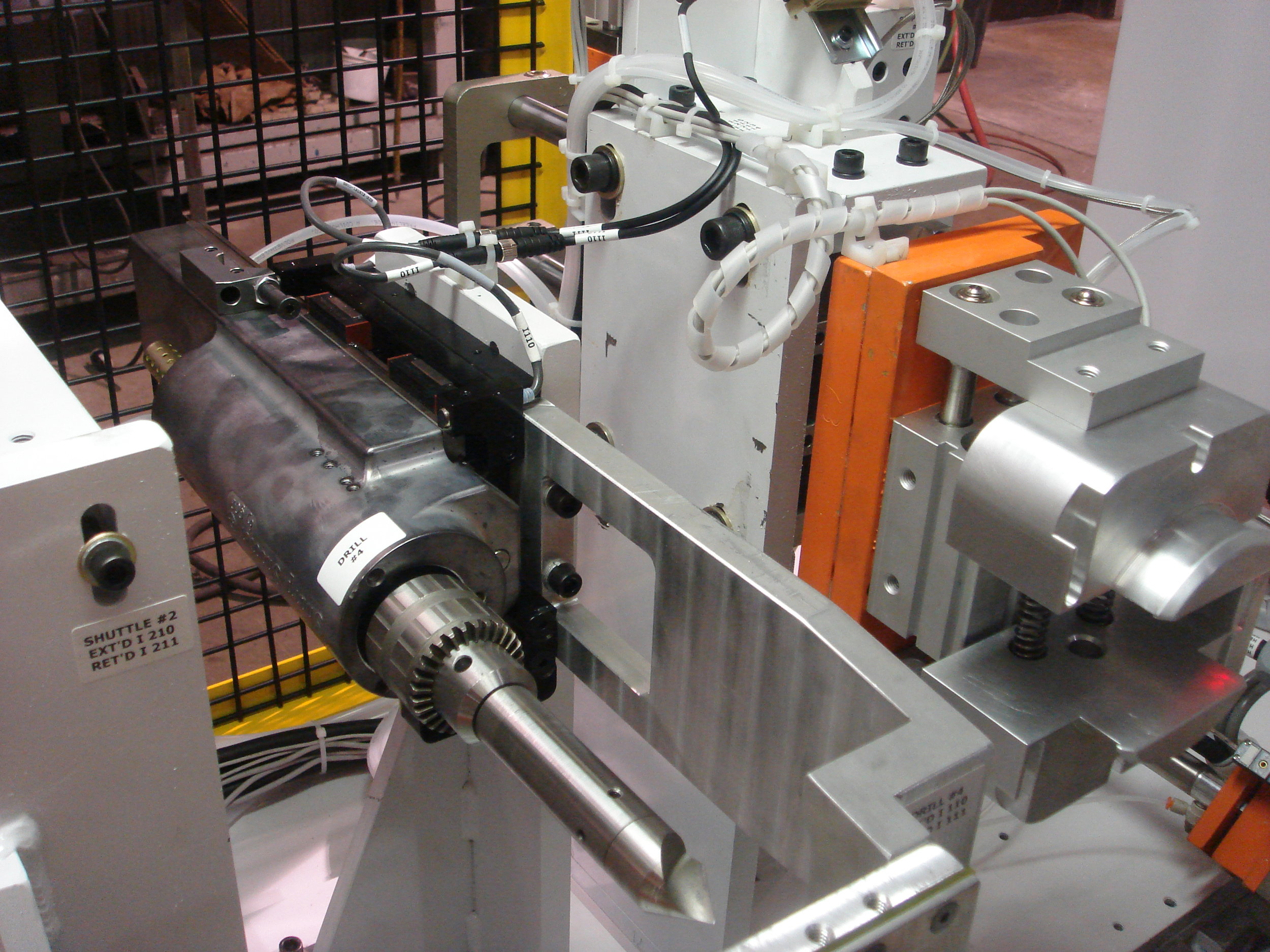

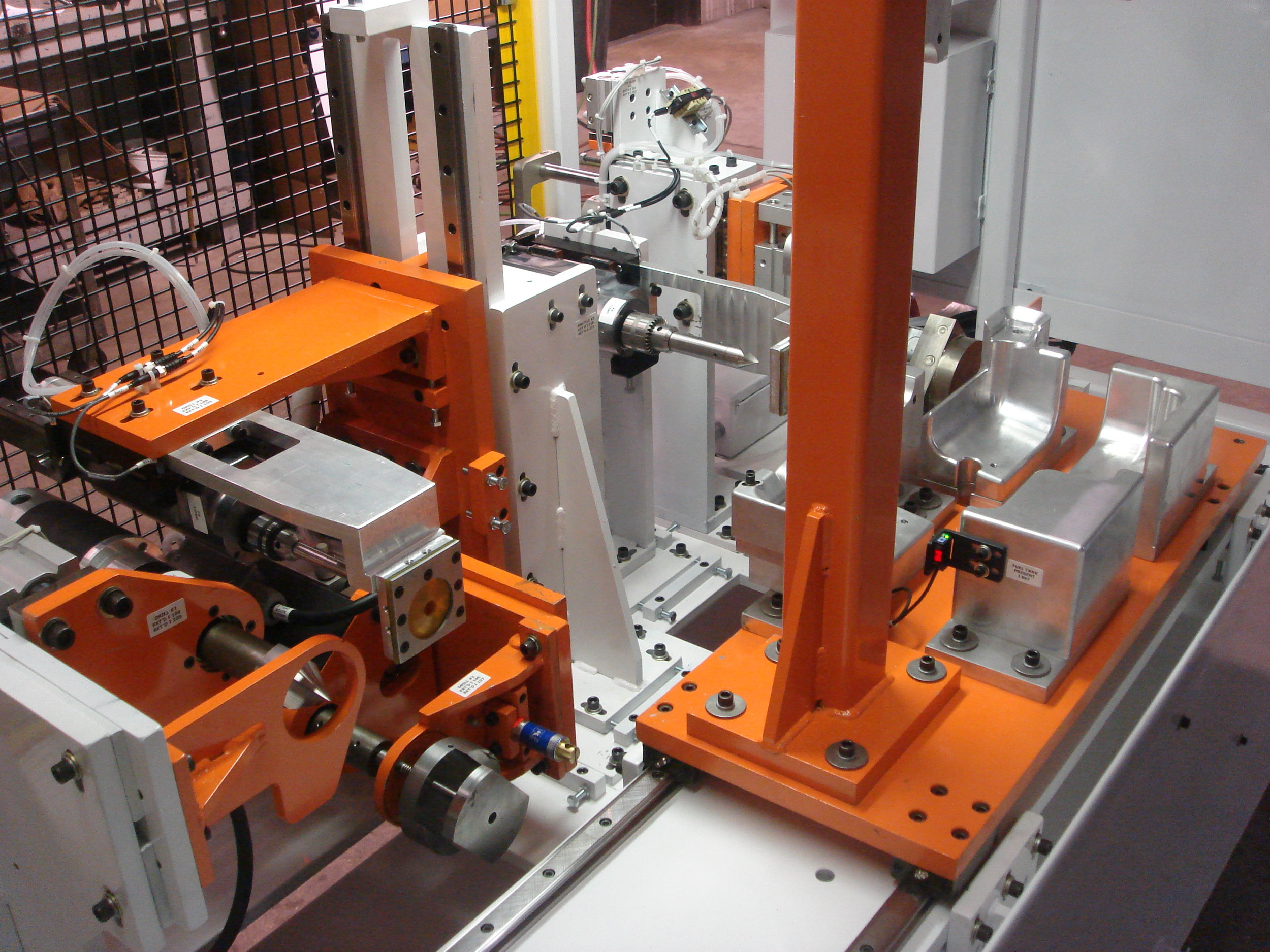

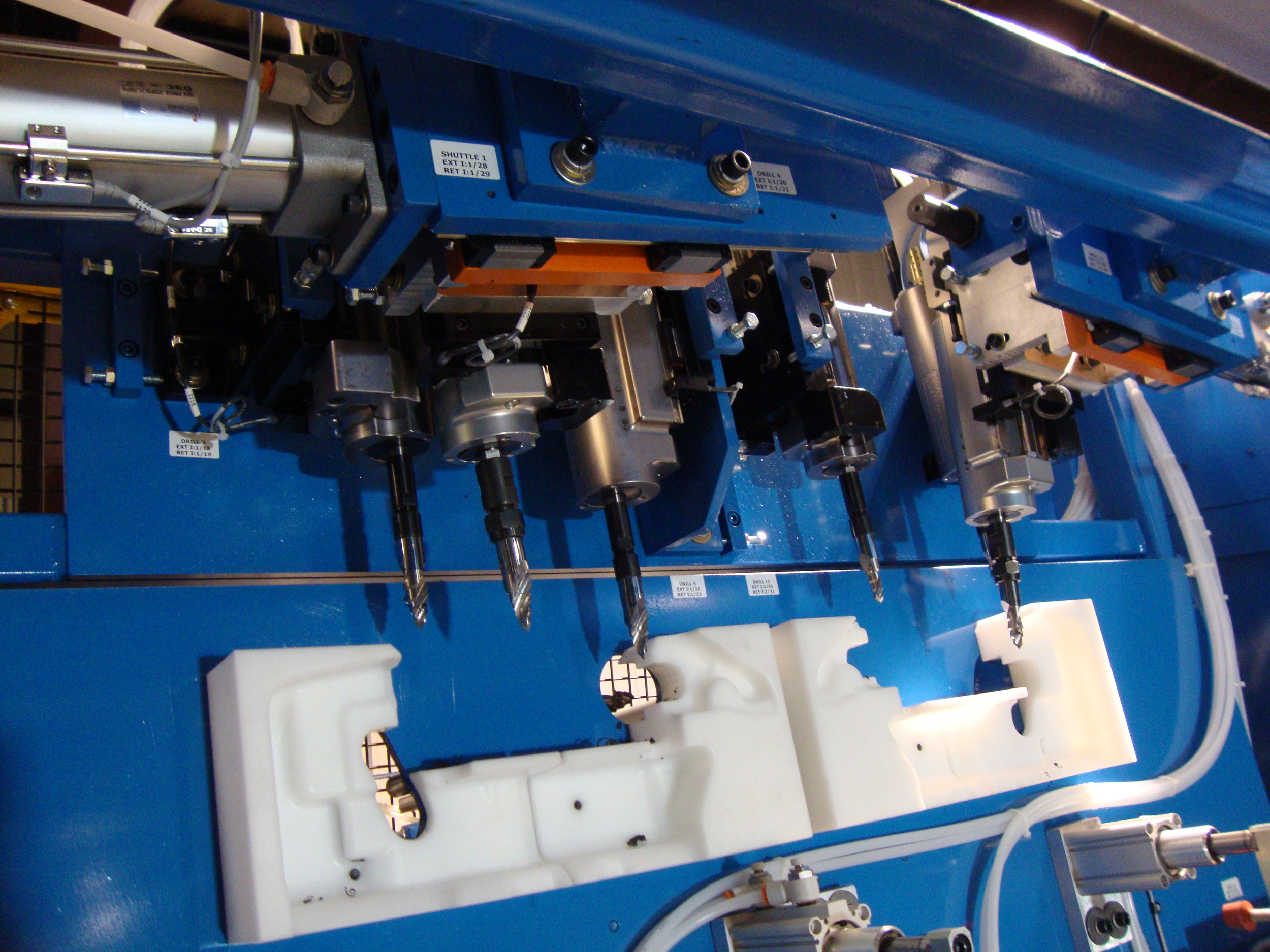

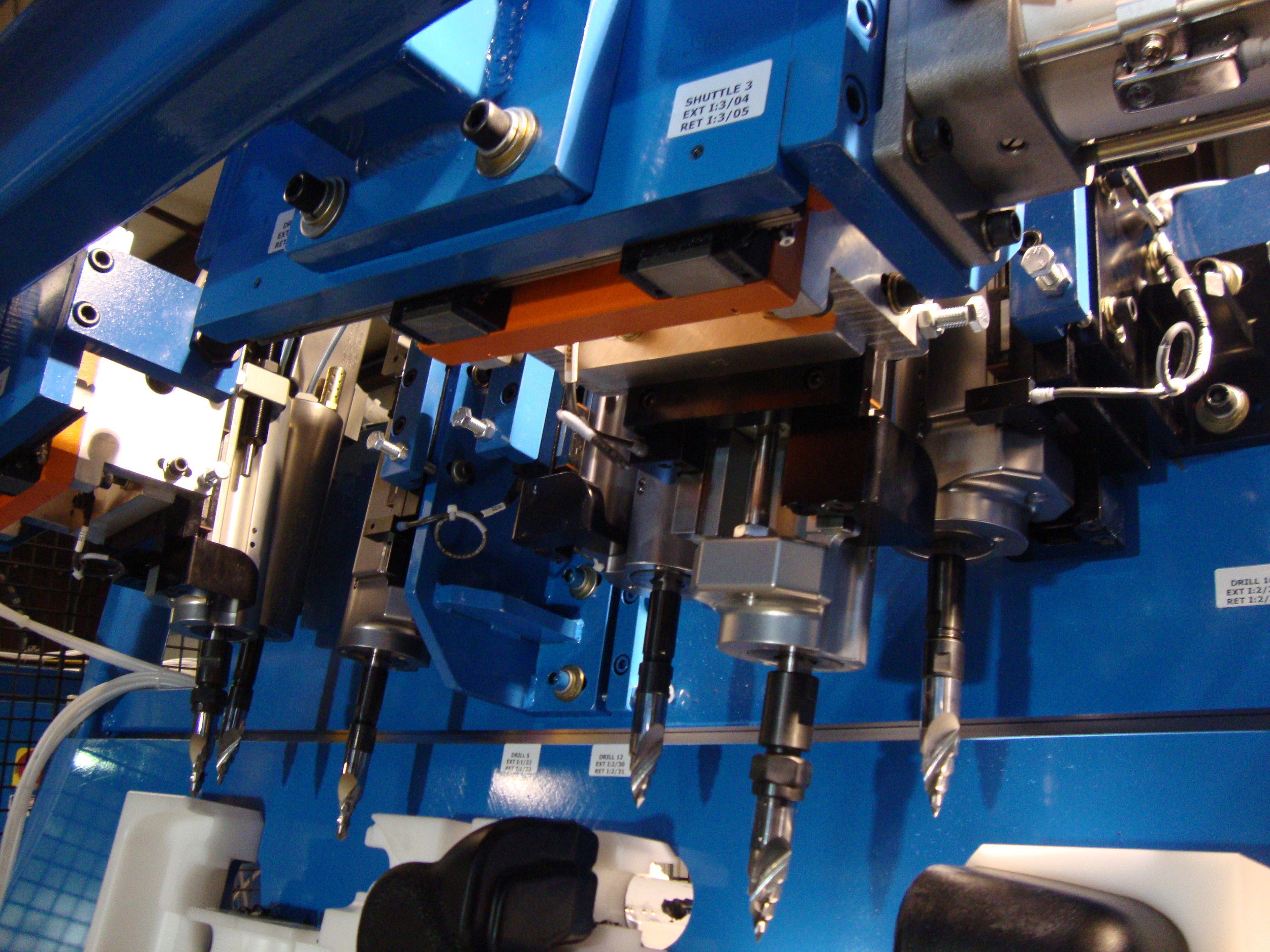

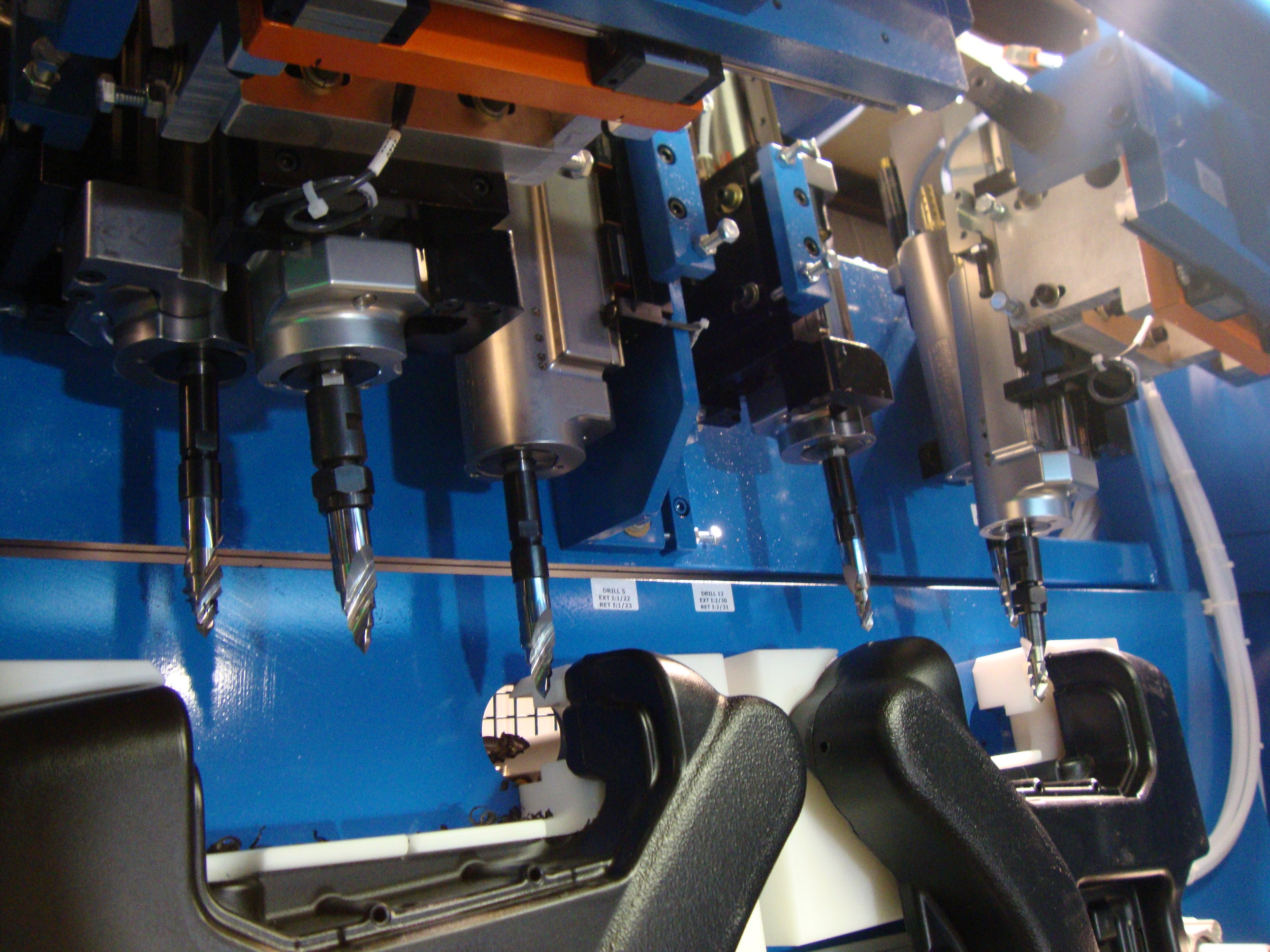

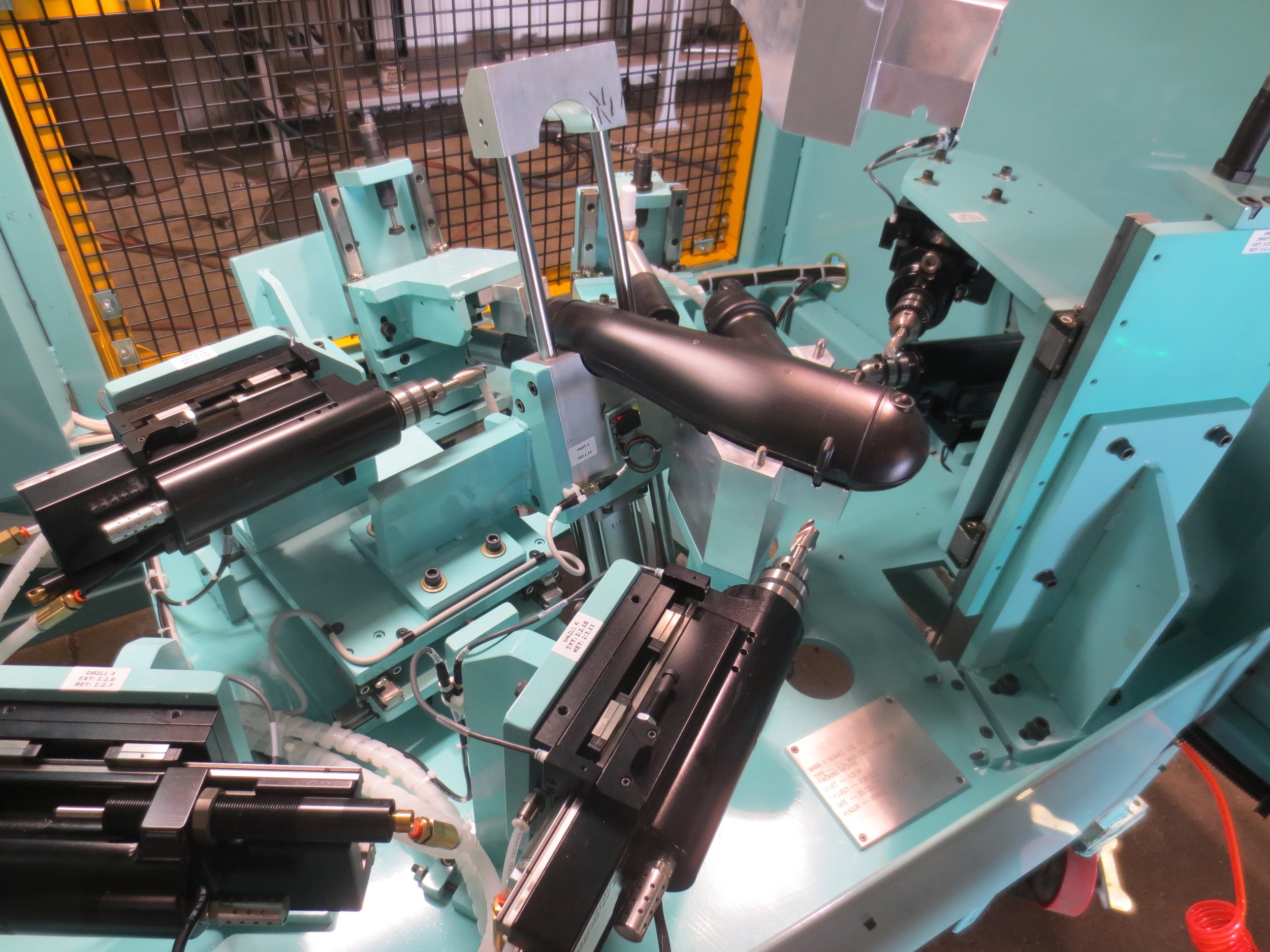

Drilling of parts is accomplished using air-driven and electric motors, depending on the size of the cutter used for the job. Sometimes drilling is done with the motor on the end of a robot, but more often than not, drill motors are mounted to a pneumatic cylinder. Punching is done using standard industry or custom machined punches mounted via a detent to a detail on the end of a pneumatic cylinder. Larger punches may be mounted to hydraulic cylinders if more force is required.

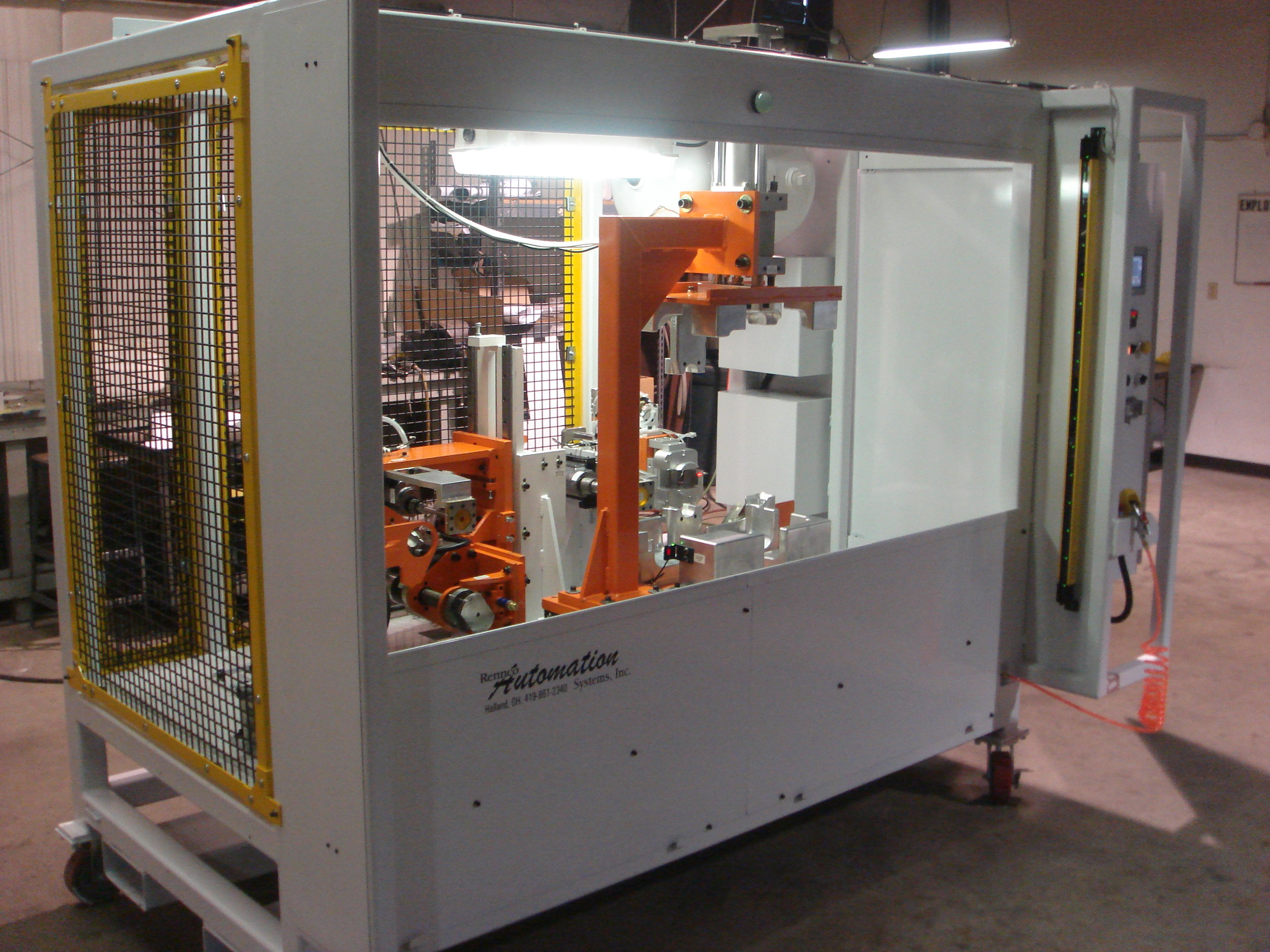

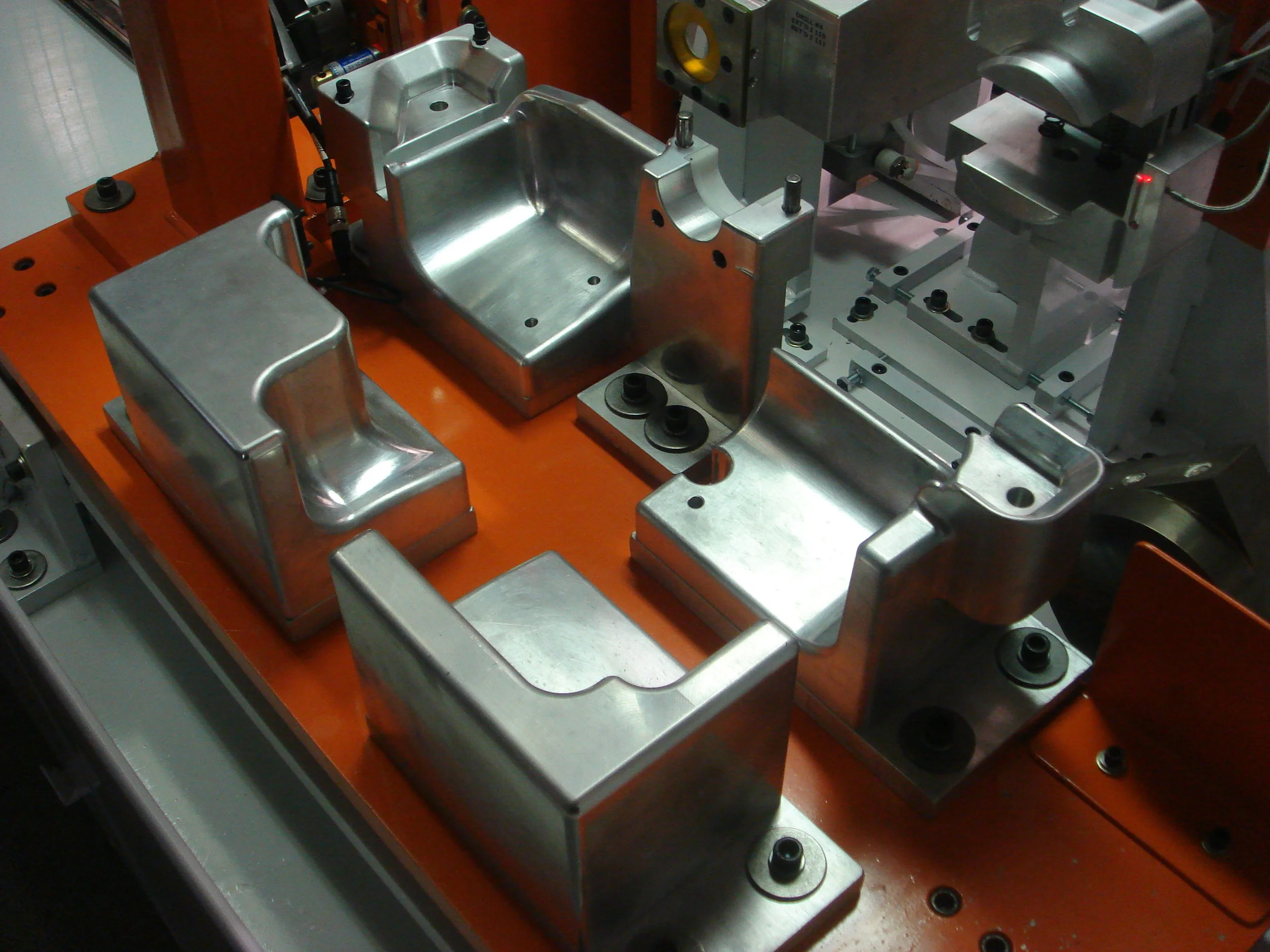

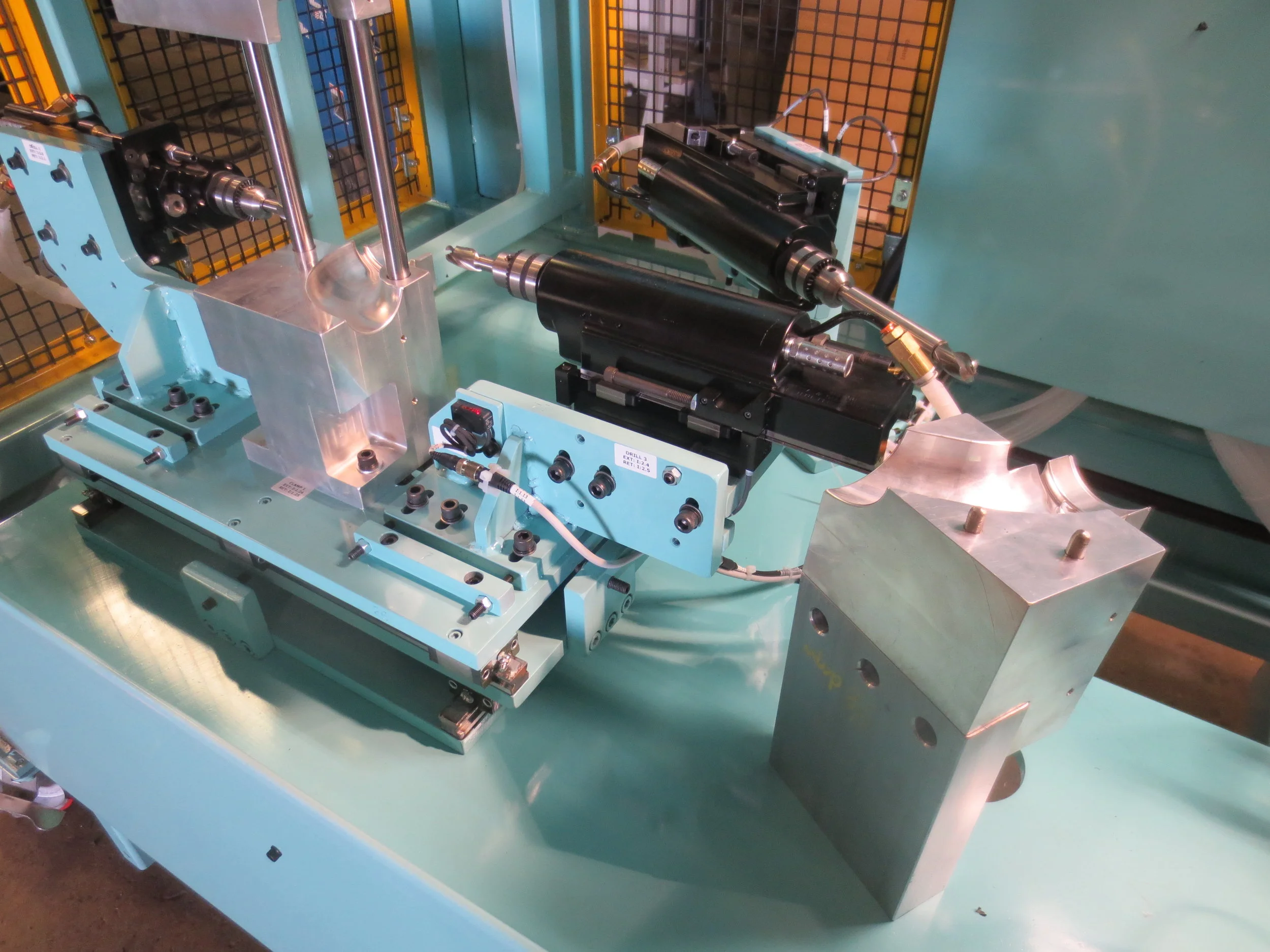

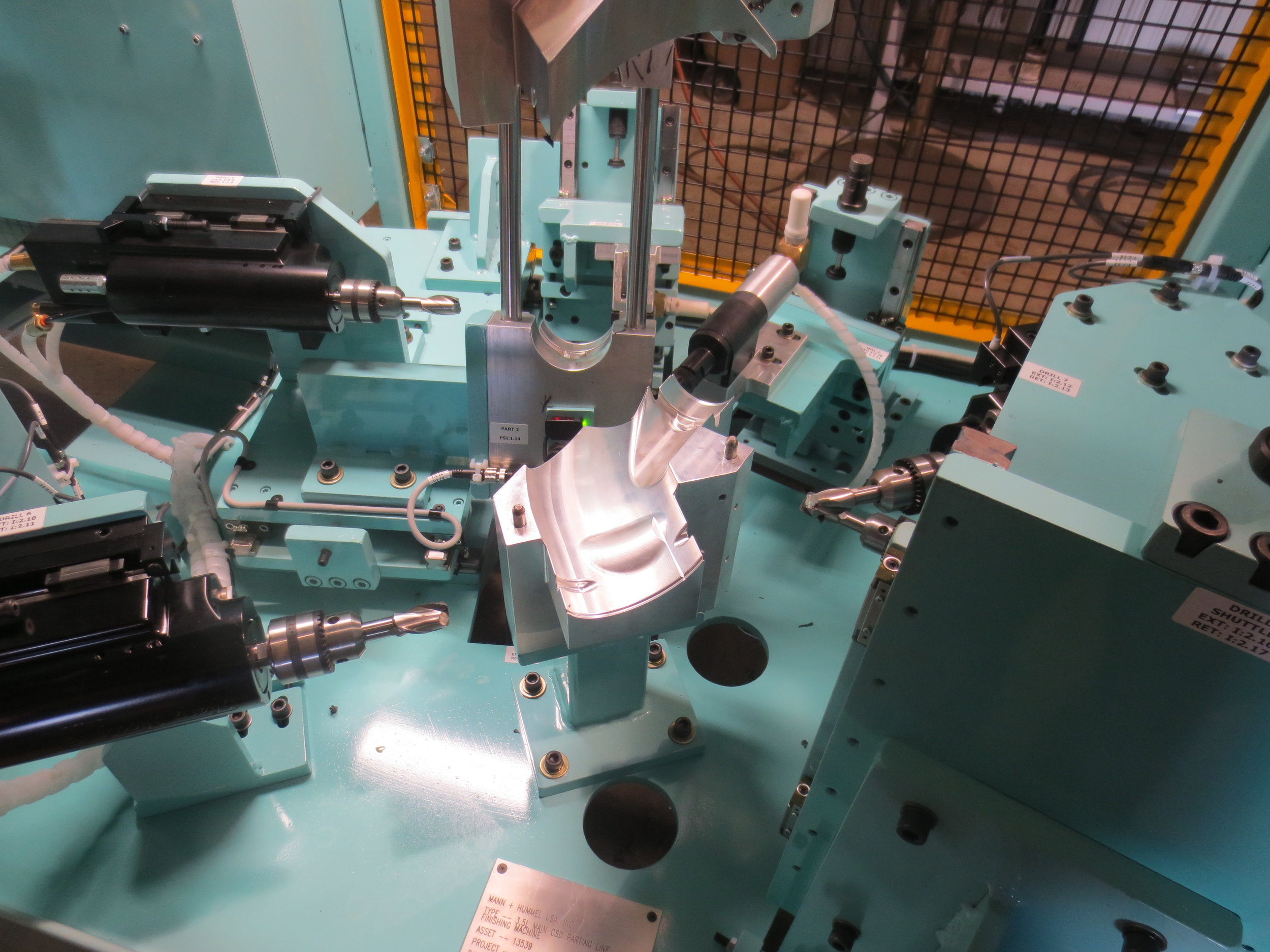

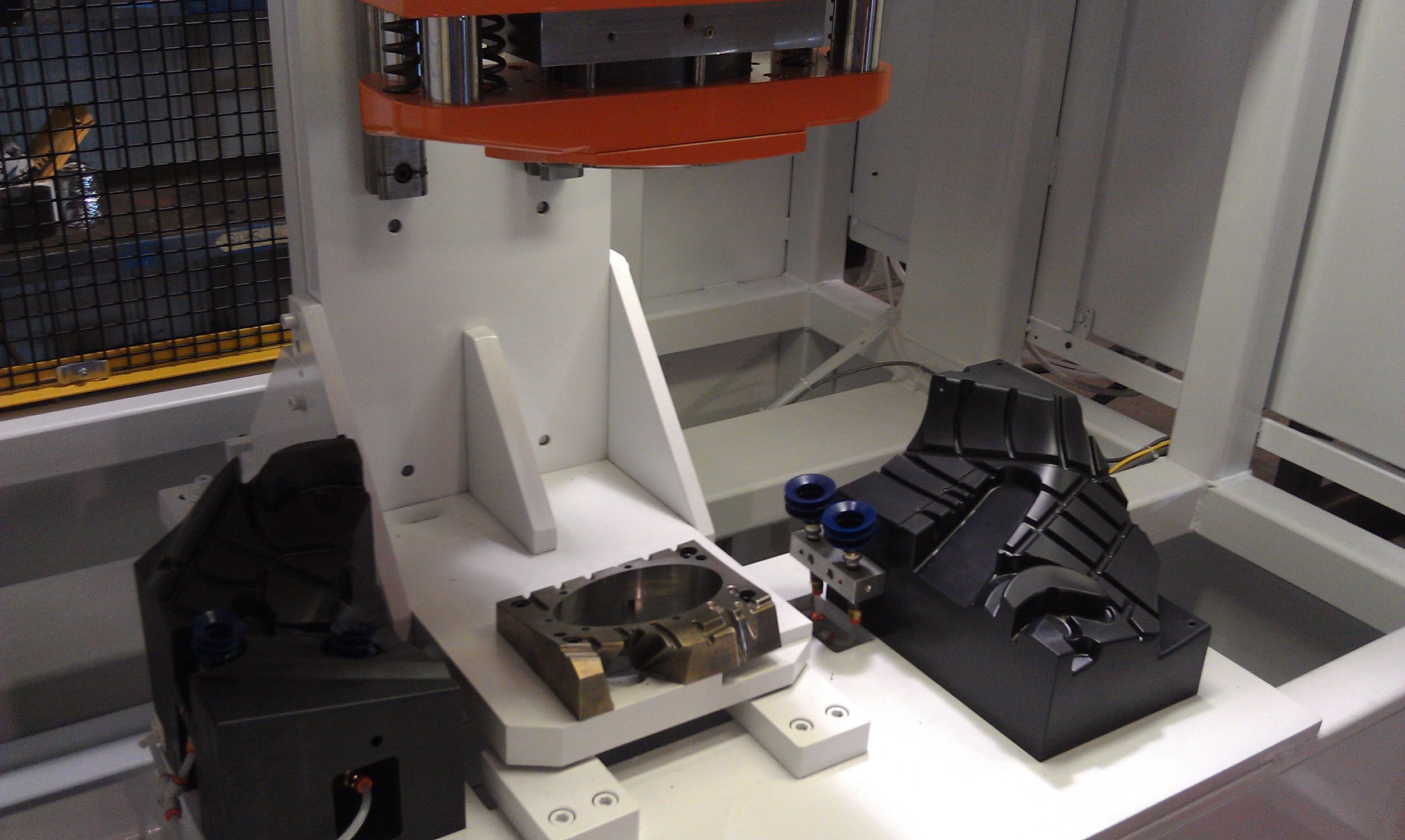

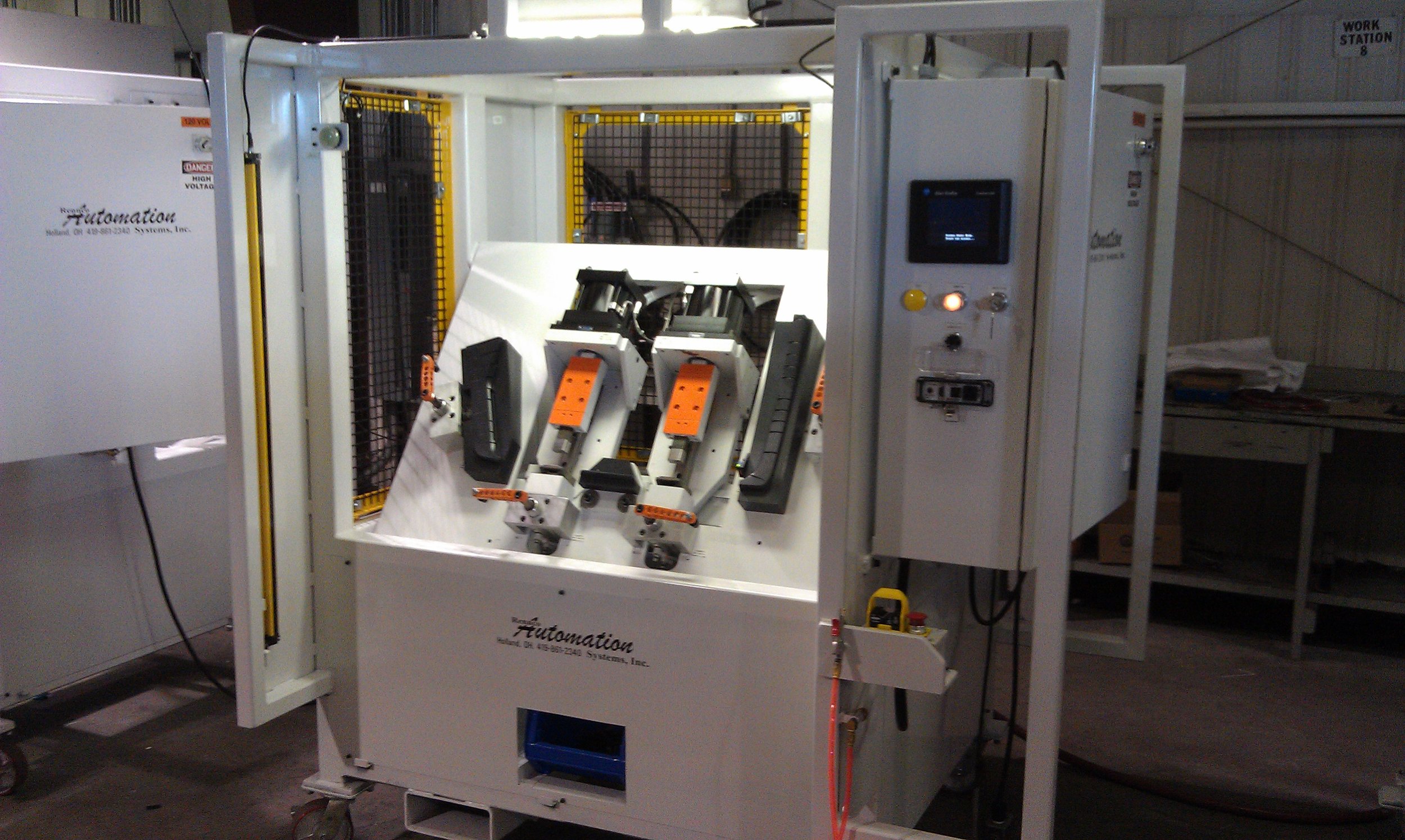

DRILL FIXTURES

These machines utilize either single/multiple pneumatic, or electric drill units to bore holes through the interior or exterior of a part to specifications. Rennco has installed thousands of various drill fixtures over the years and utilizes the Sharp Shooter Drill brand on our secondary finishing fixtures. This drill unit is specially designed and built to handle the rigors of any production setting. For additional information on Sharp Shooter Drills, click here.

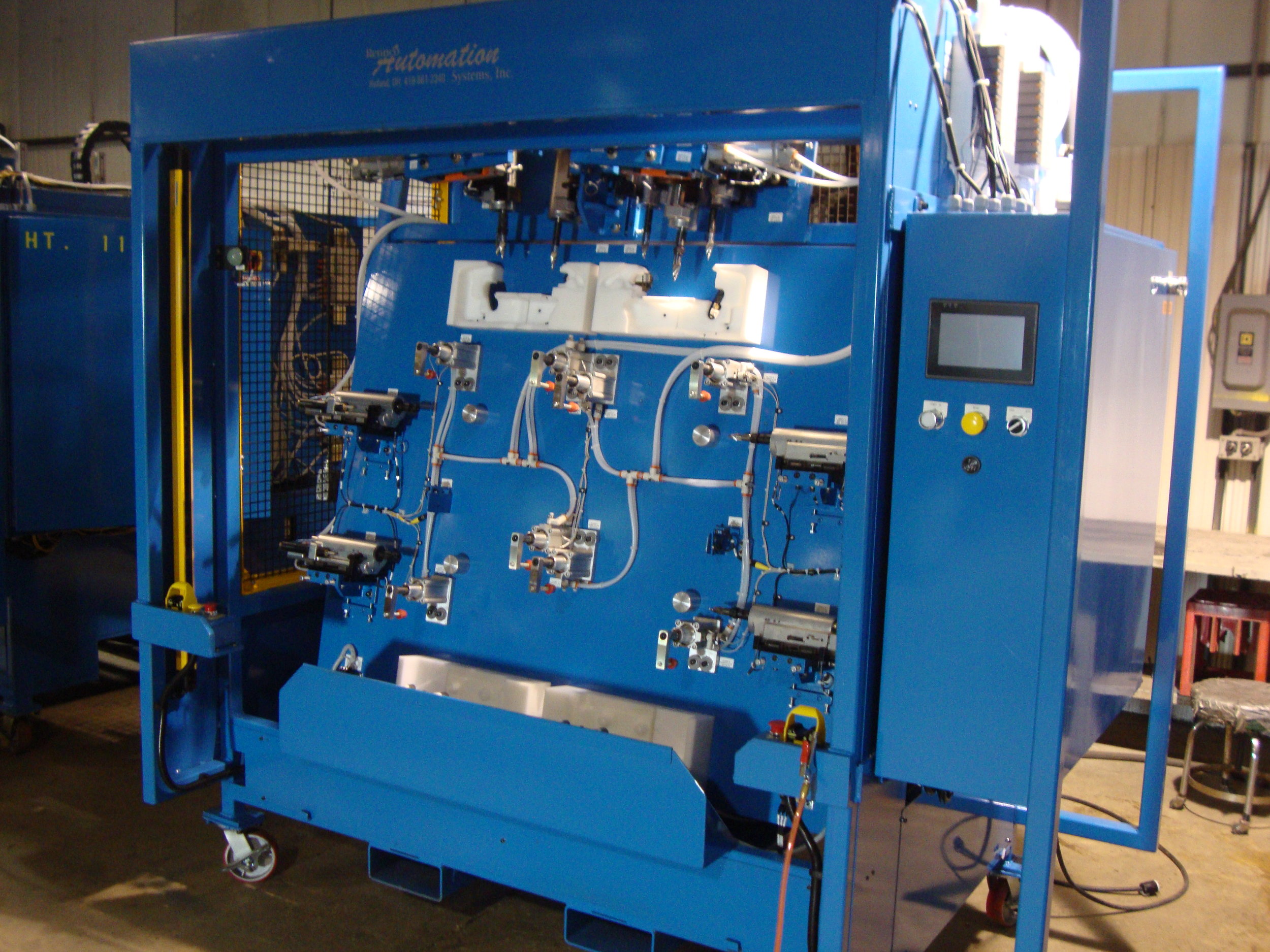

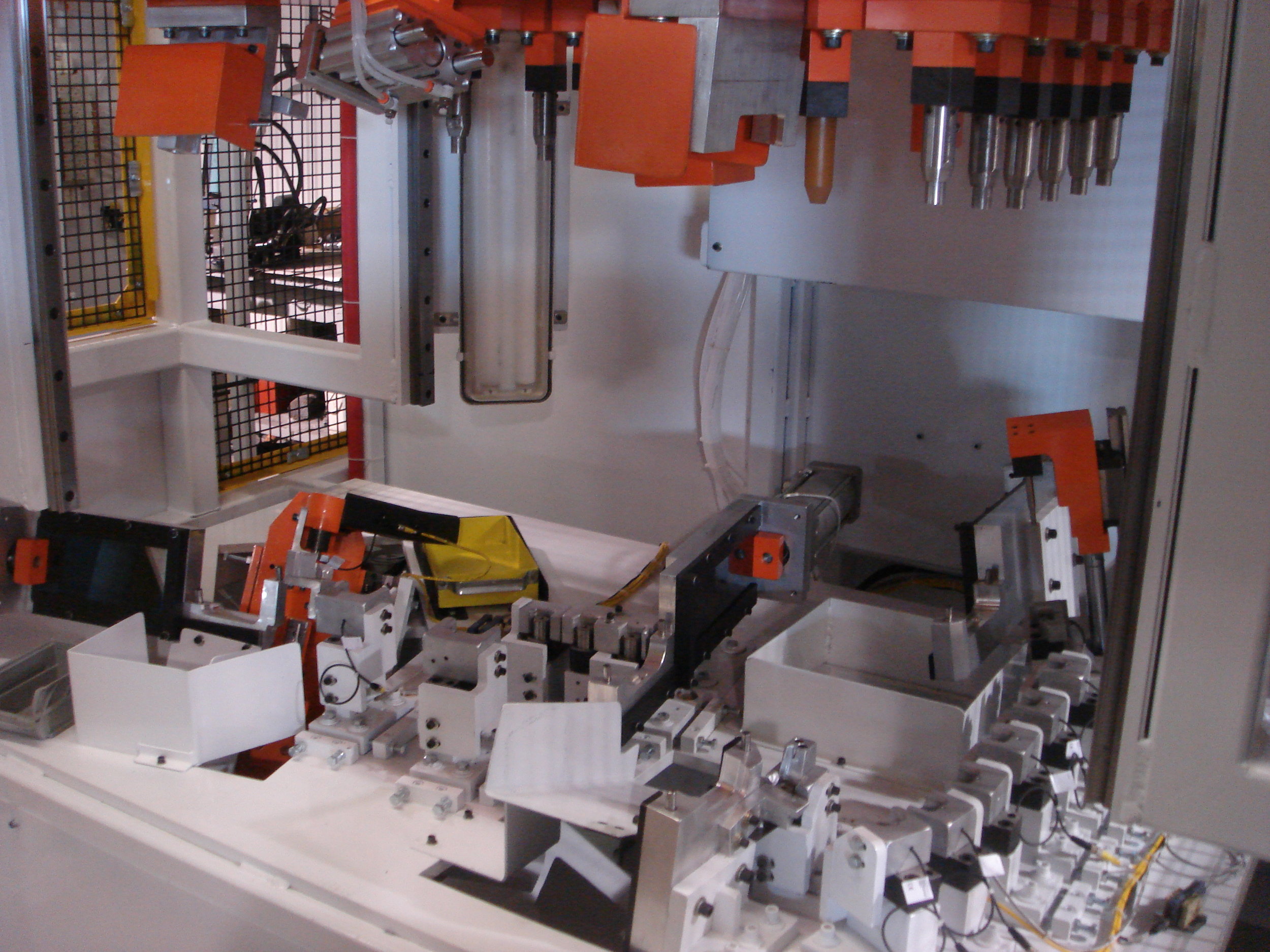

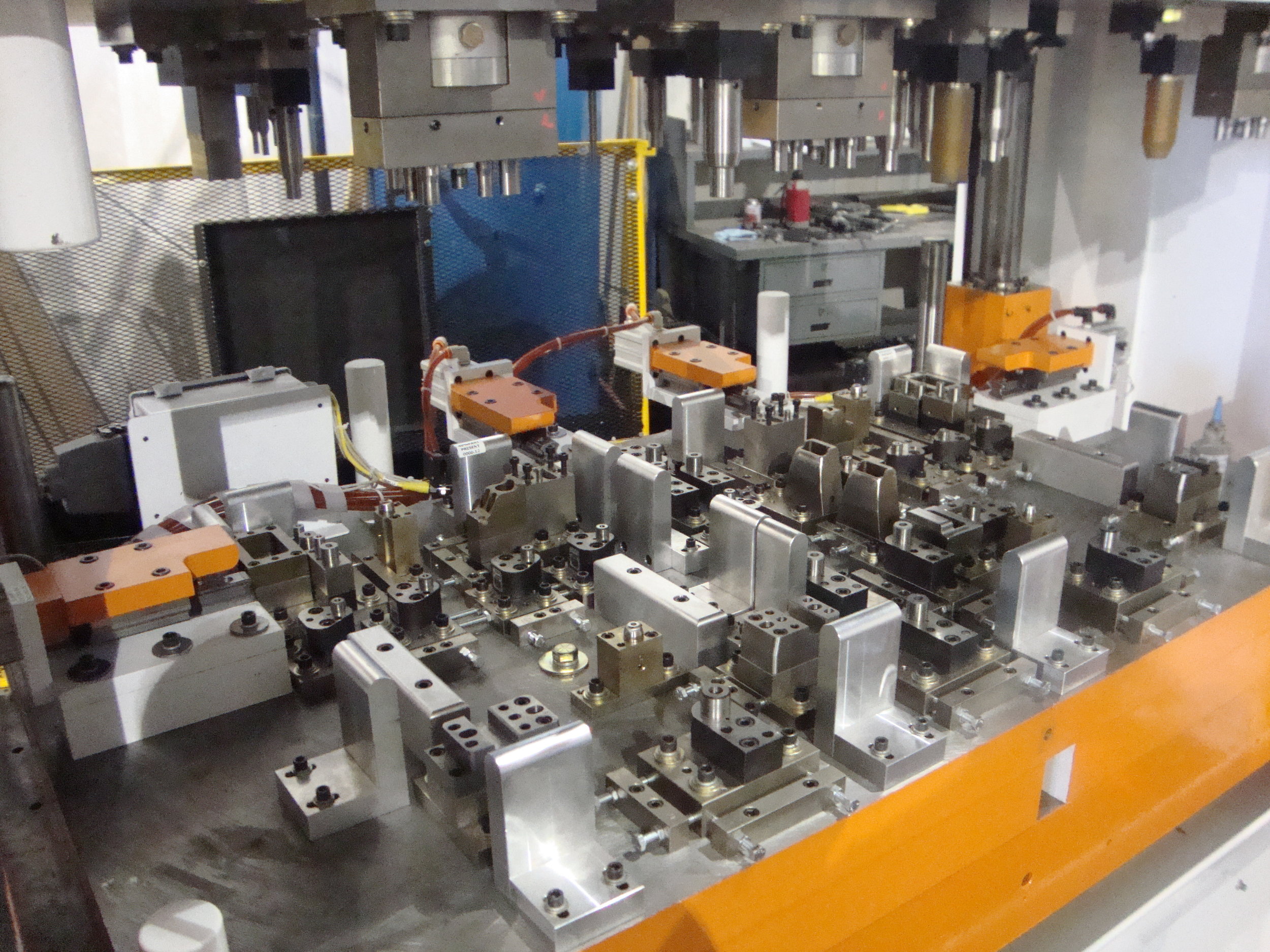

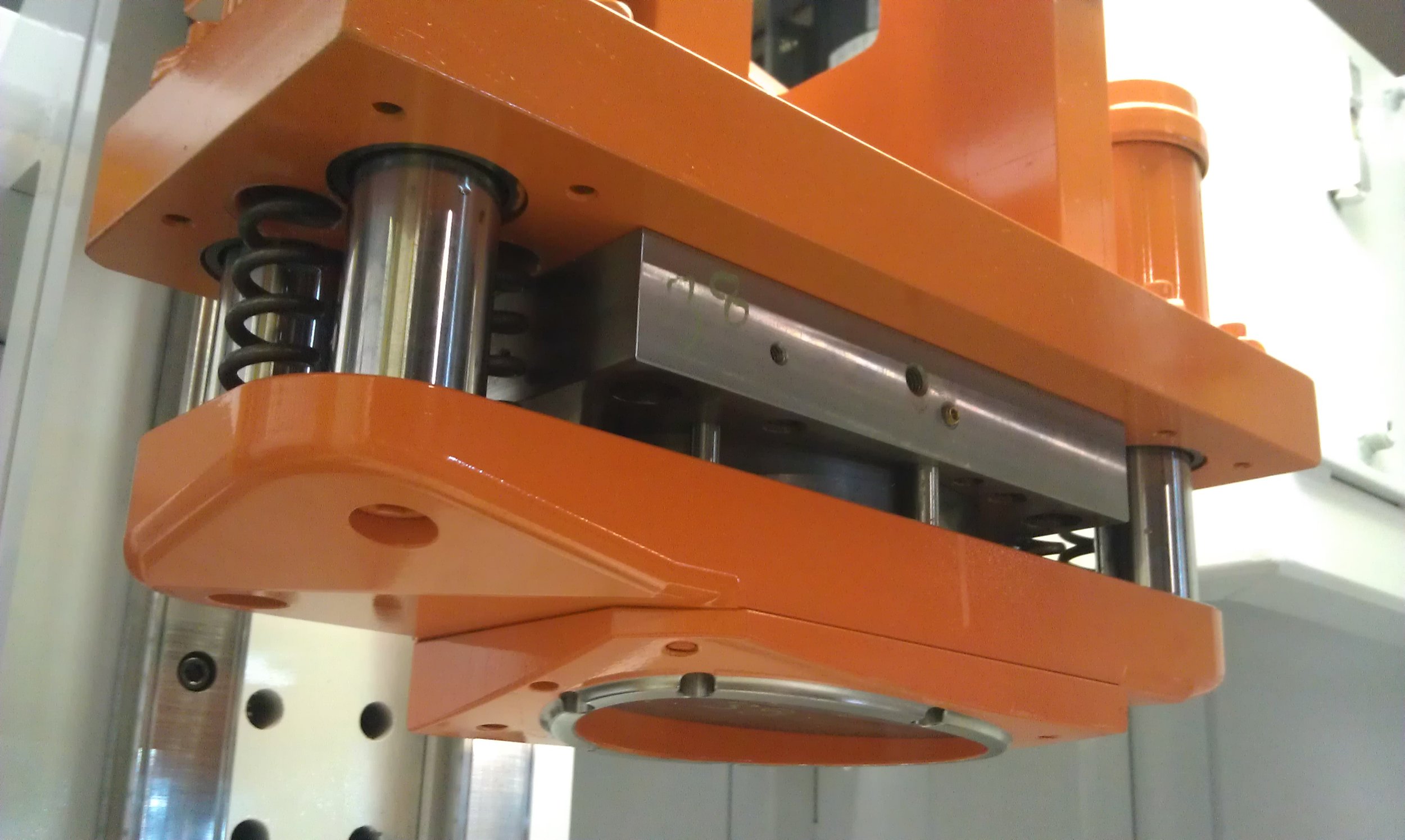

PUNCH FIXTURES

These machines utilize industry standard punch bits or custom ground punches fastened via detents to details that are mounted to either a pneumatic or hydraulic cylinder, depending on the size and shape of the hole being punched.