Here at Rennco, we frequently use robotics in many of our machine applications. They provide endless possibilities in an effort to satisfy industrial production needs. Our applications range from stand alone fixtures to complete cell automation, and with full programming capabilities on site we are able to customize machines to do a wide range of functions. We have experience with many brands of robots.

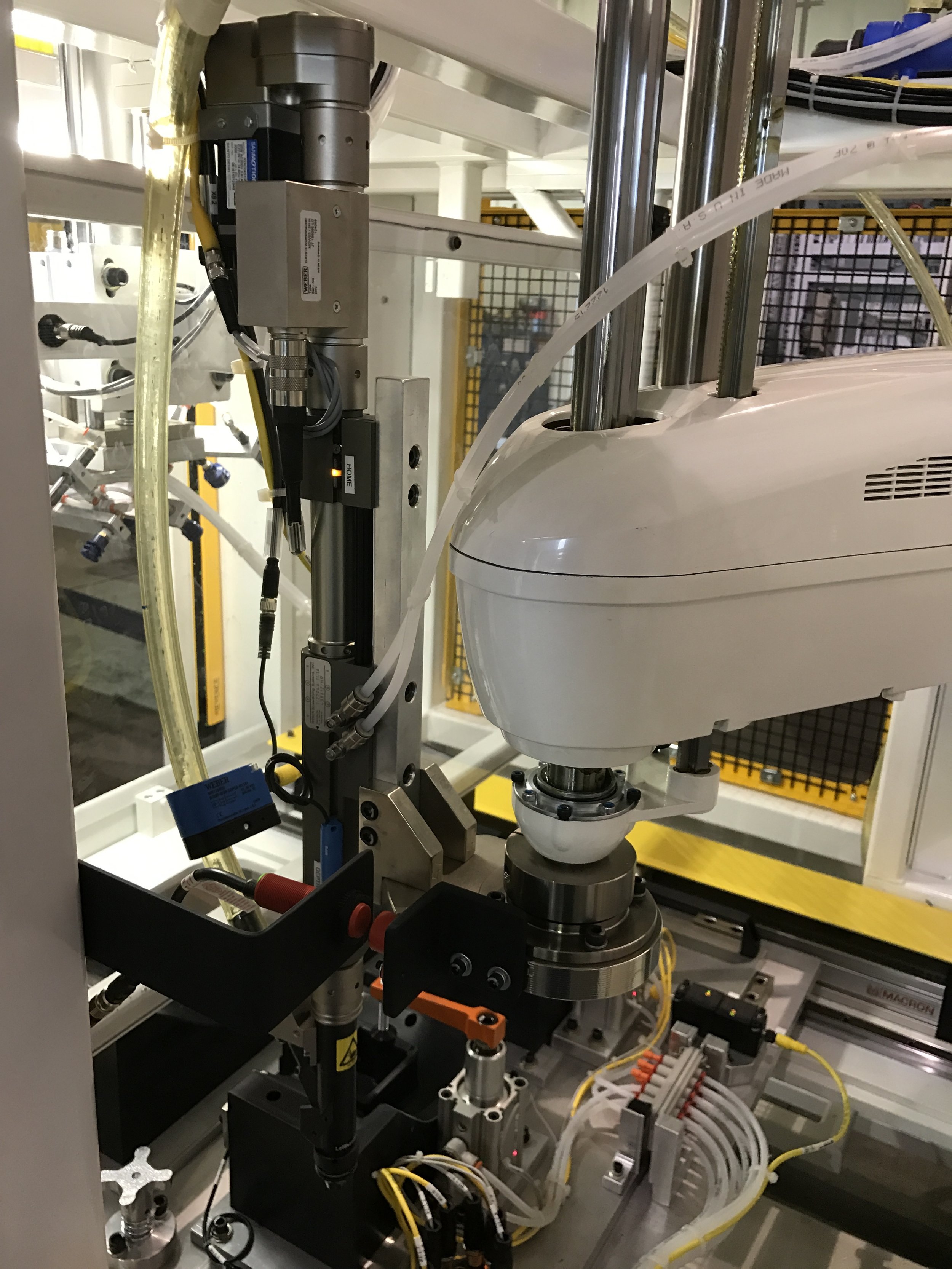

ROBOTIC uLTRA-SONIC wELDING

An industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to work pieces being held together under pressure to create a solid-state weld. It is commonly used for plastics. Ultrasonic welding alleviates the need for bolts, nails, soldering, or adhesives necessary to bind the materials together.

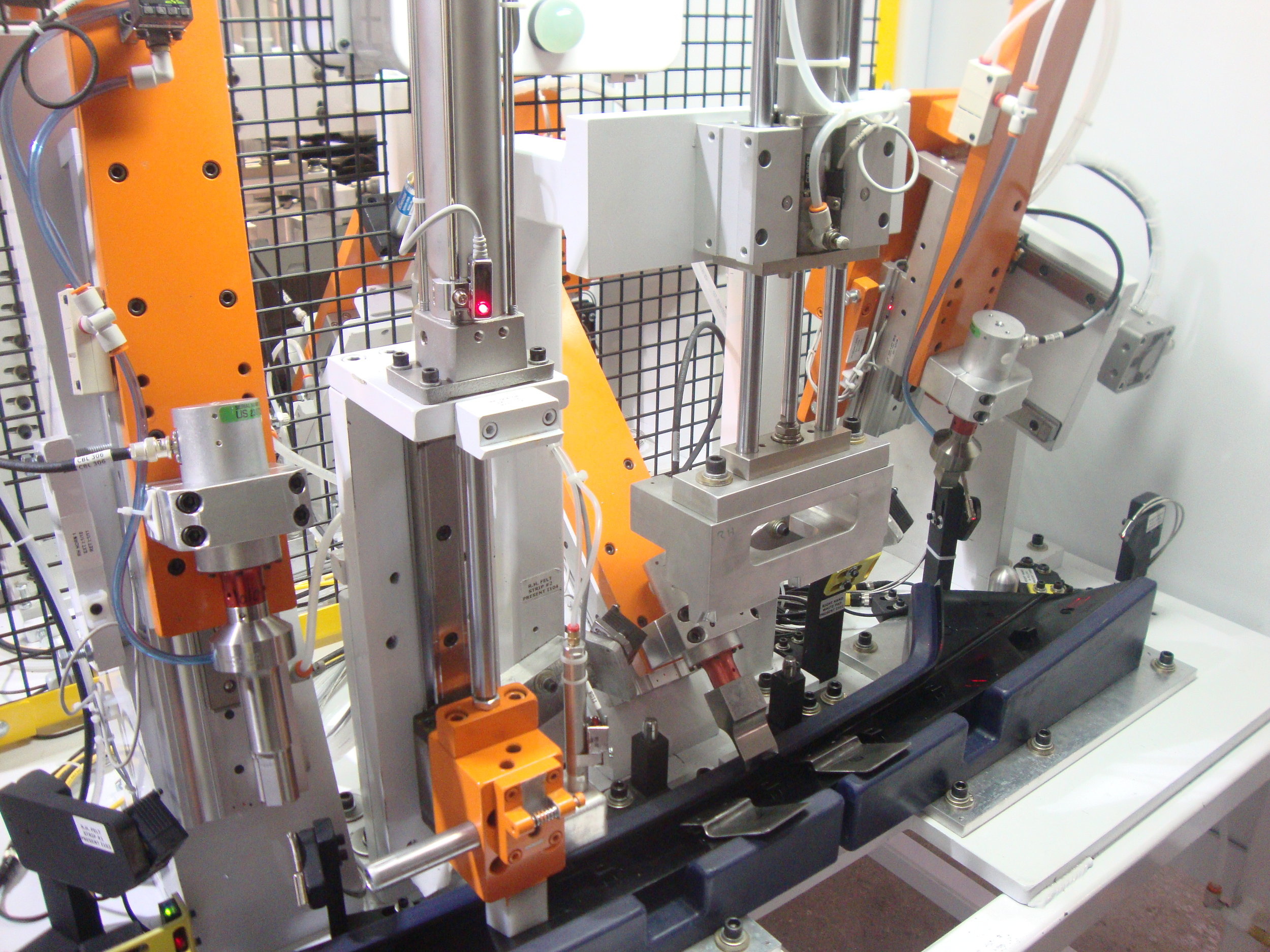

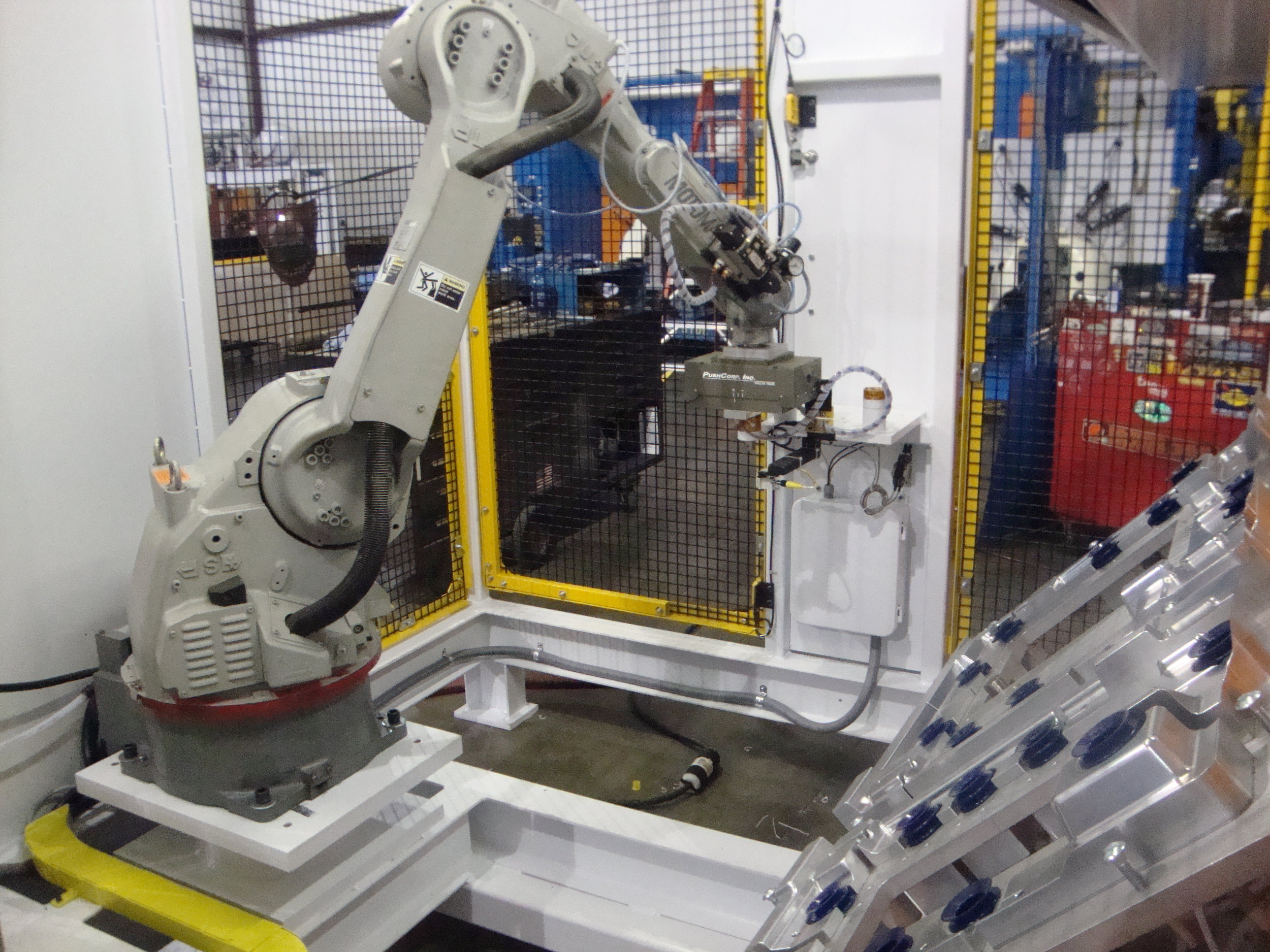

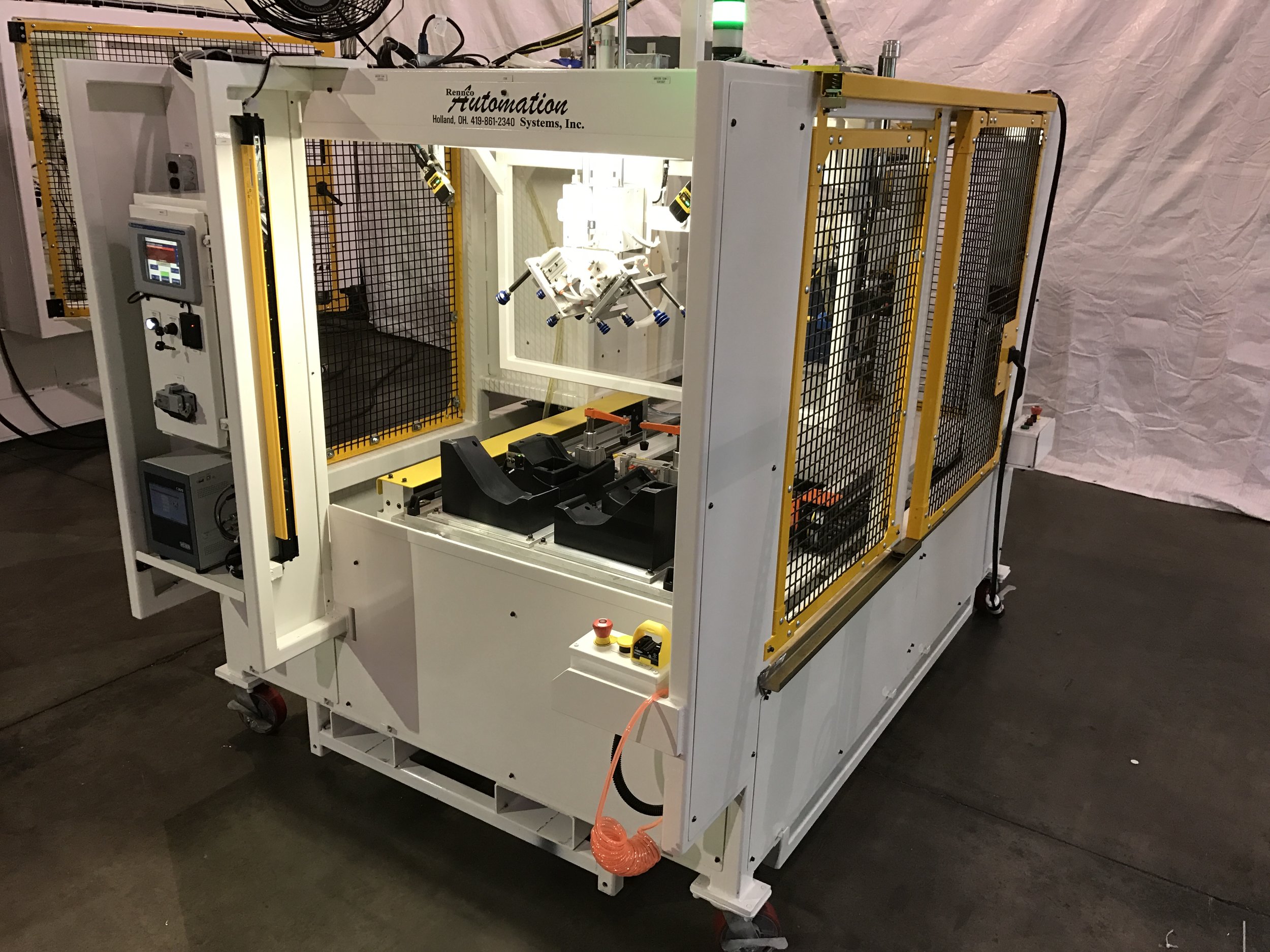

ROBOTIC CLIP INSTALL

Commonly used as a value added item to compliment a wide range of finishing fixtures. We have experience in many types fasteners whether it be J-clips, pale nuts, U- nuts, Christmas tree fasteners, etc.

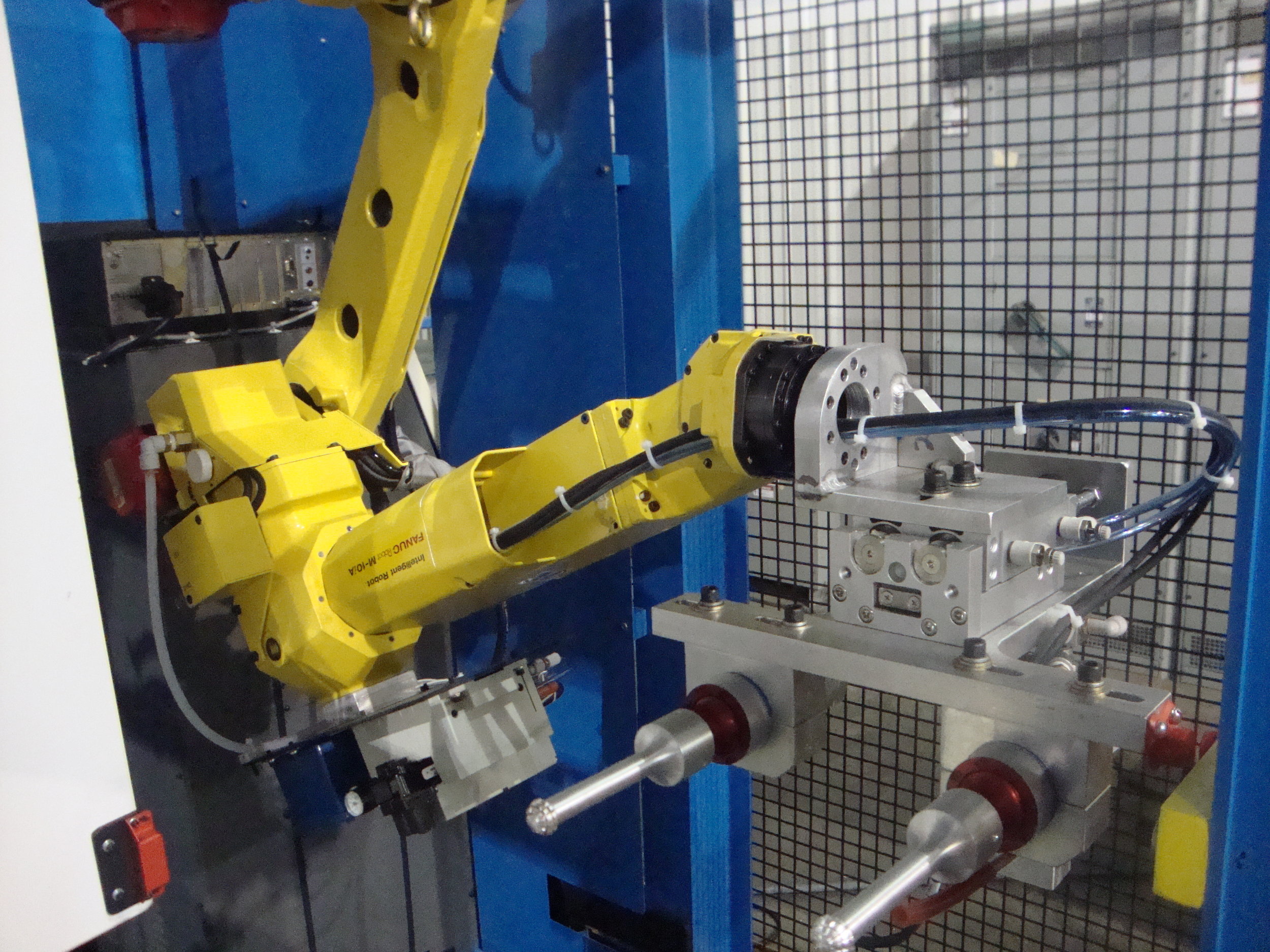

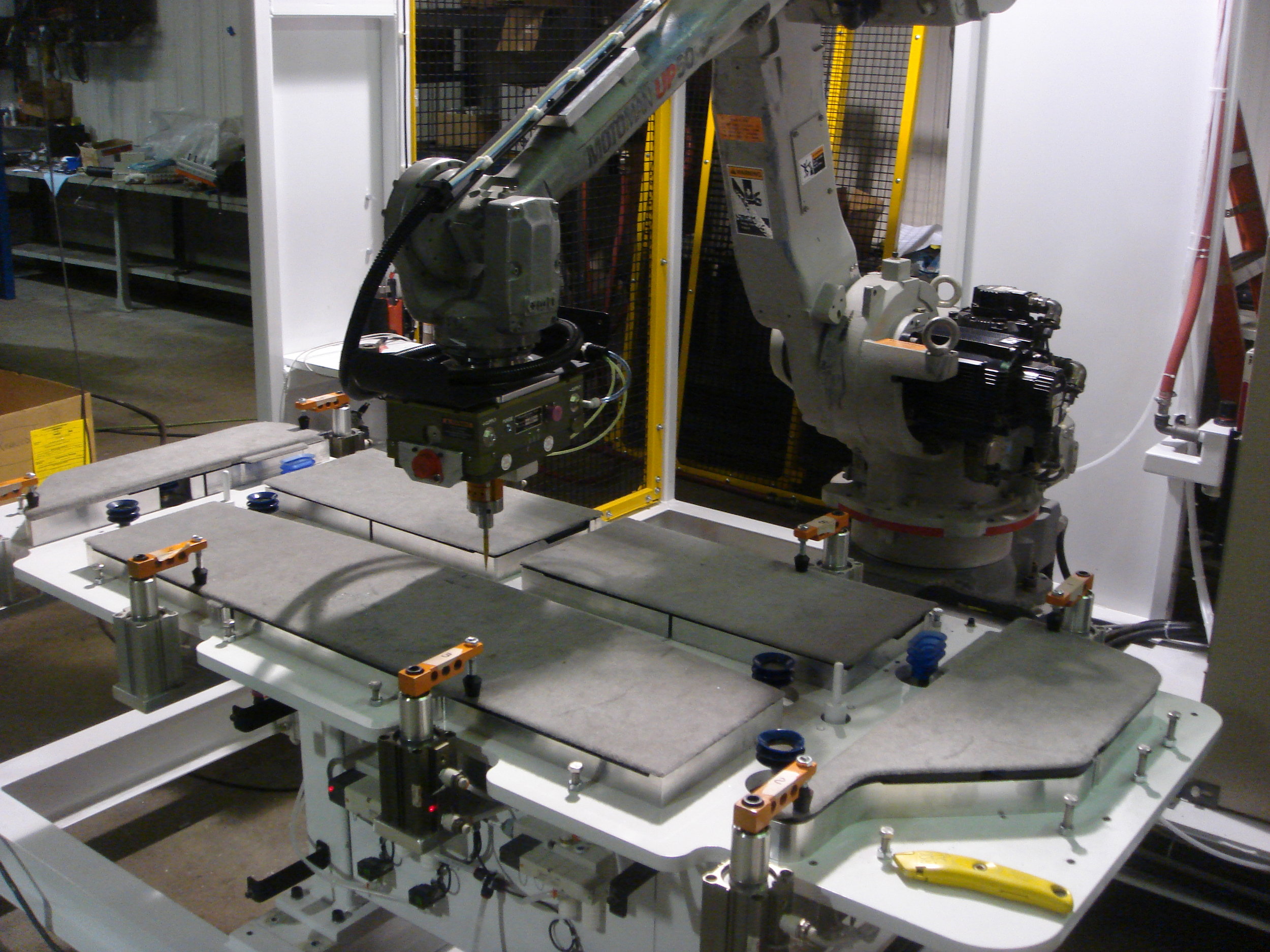

ROBOTIC KNIFE TRIMMING

A rigid knife blade in end-of-arm tooling, designed to trim the excess plastic scrap off of a blow molded part. These robot cells eliminate labor time in manually trimming out a finished product from its molded state when it comes out of a molding press.

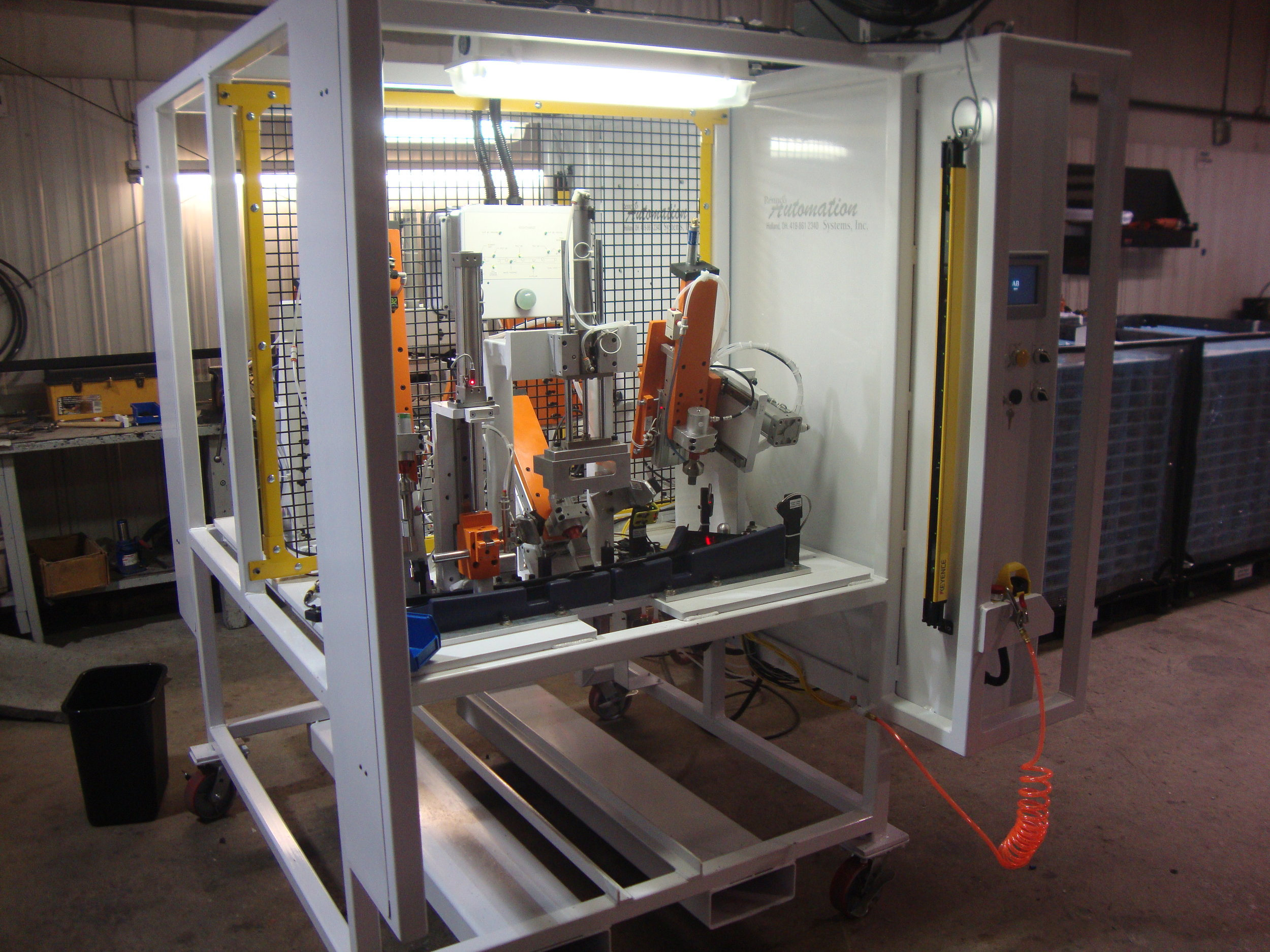

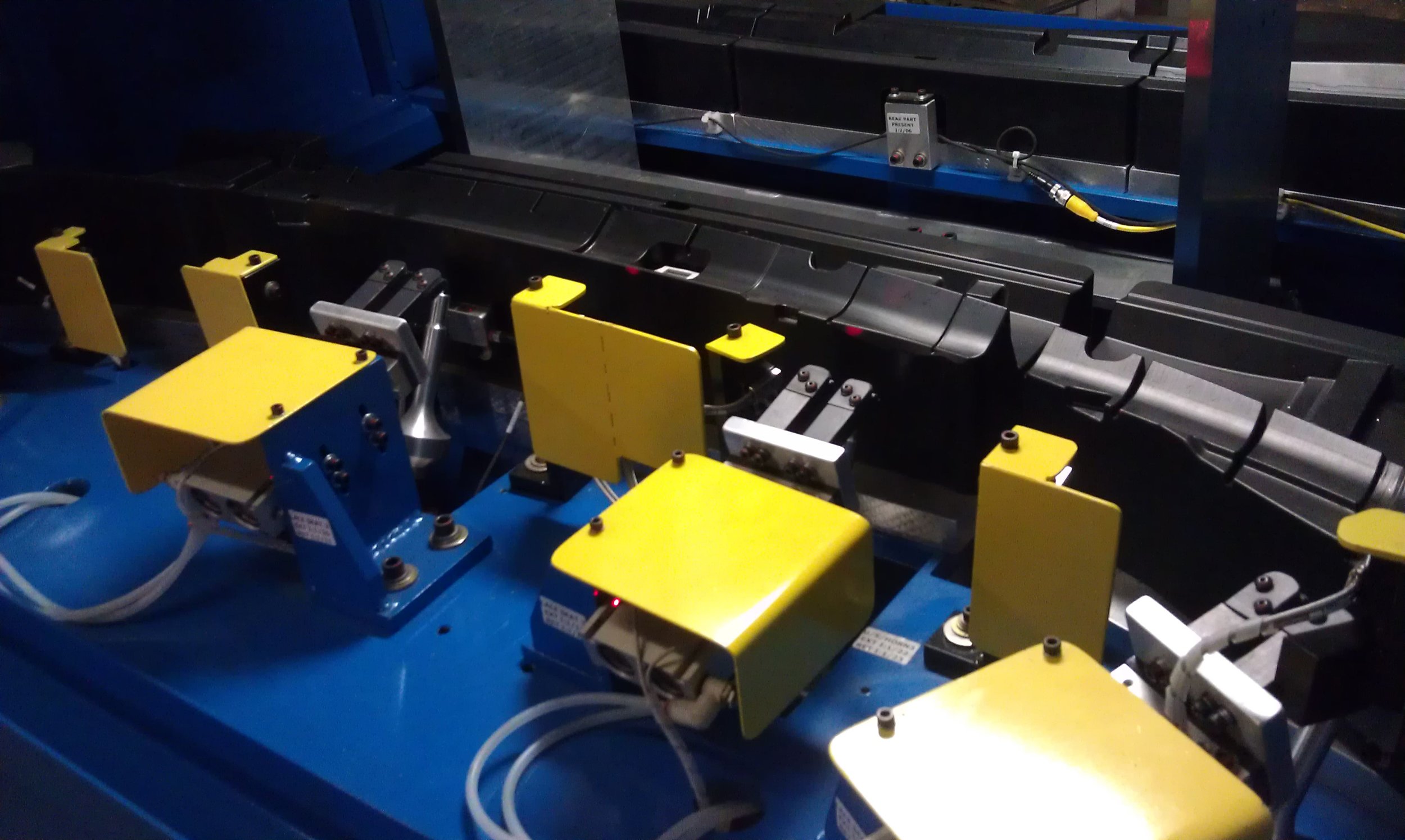

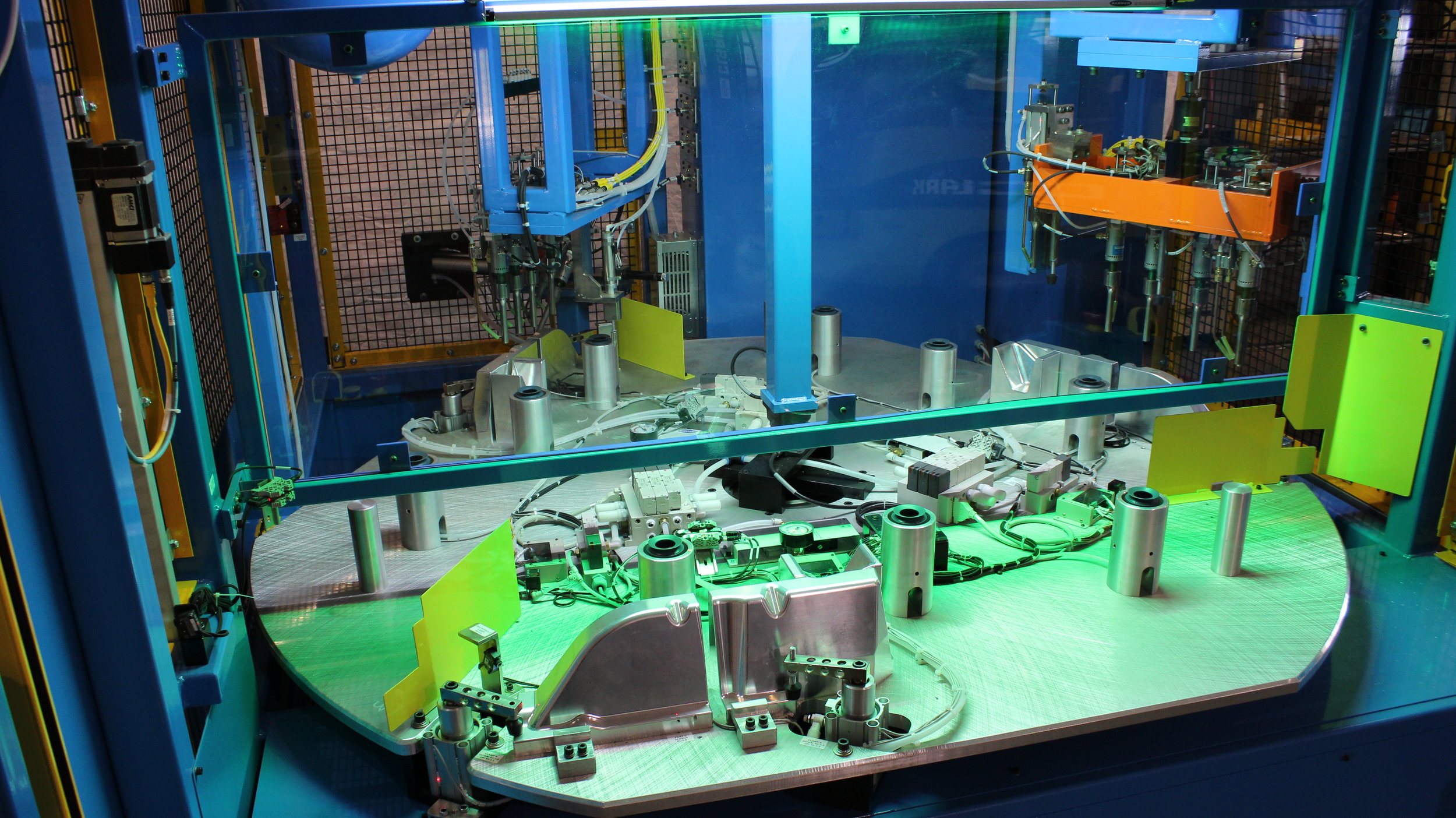

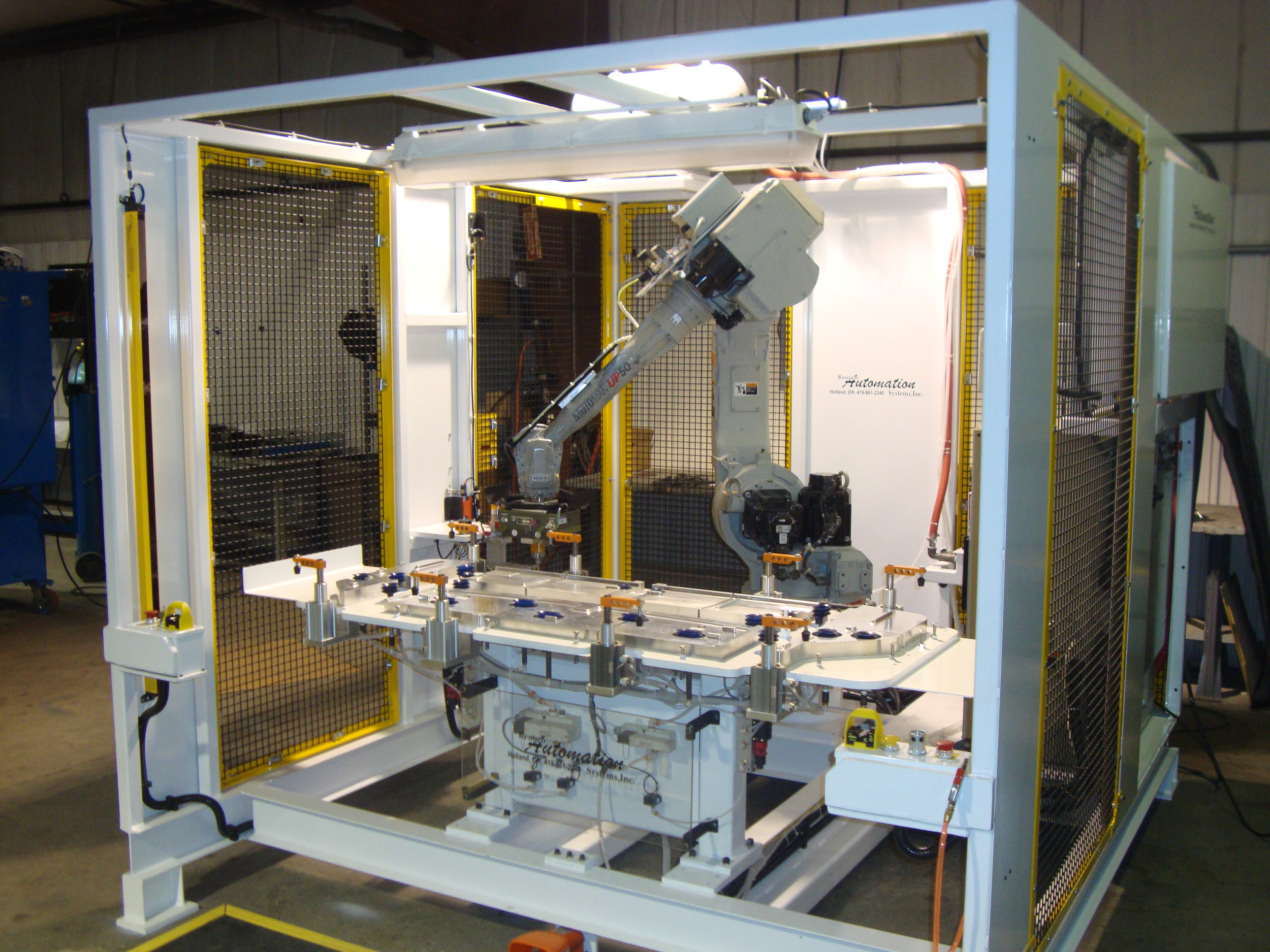

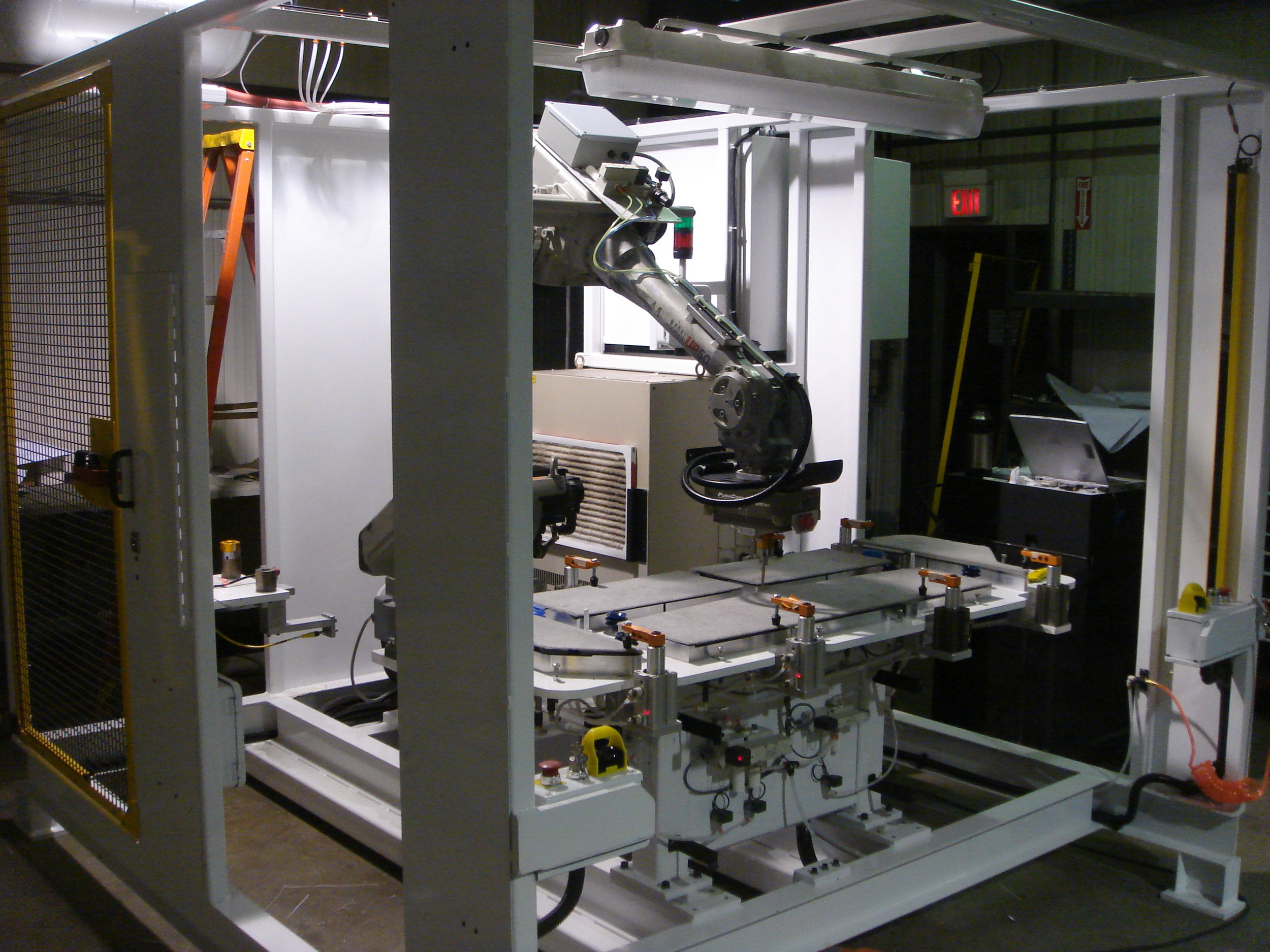

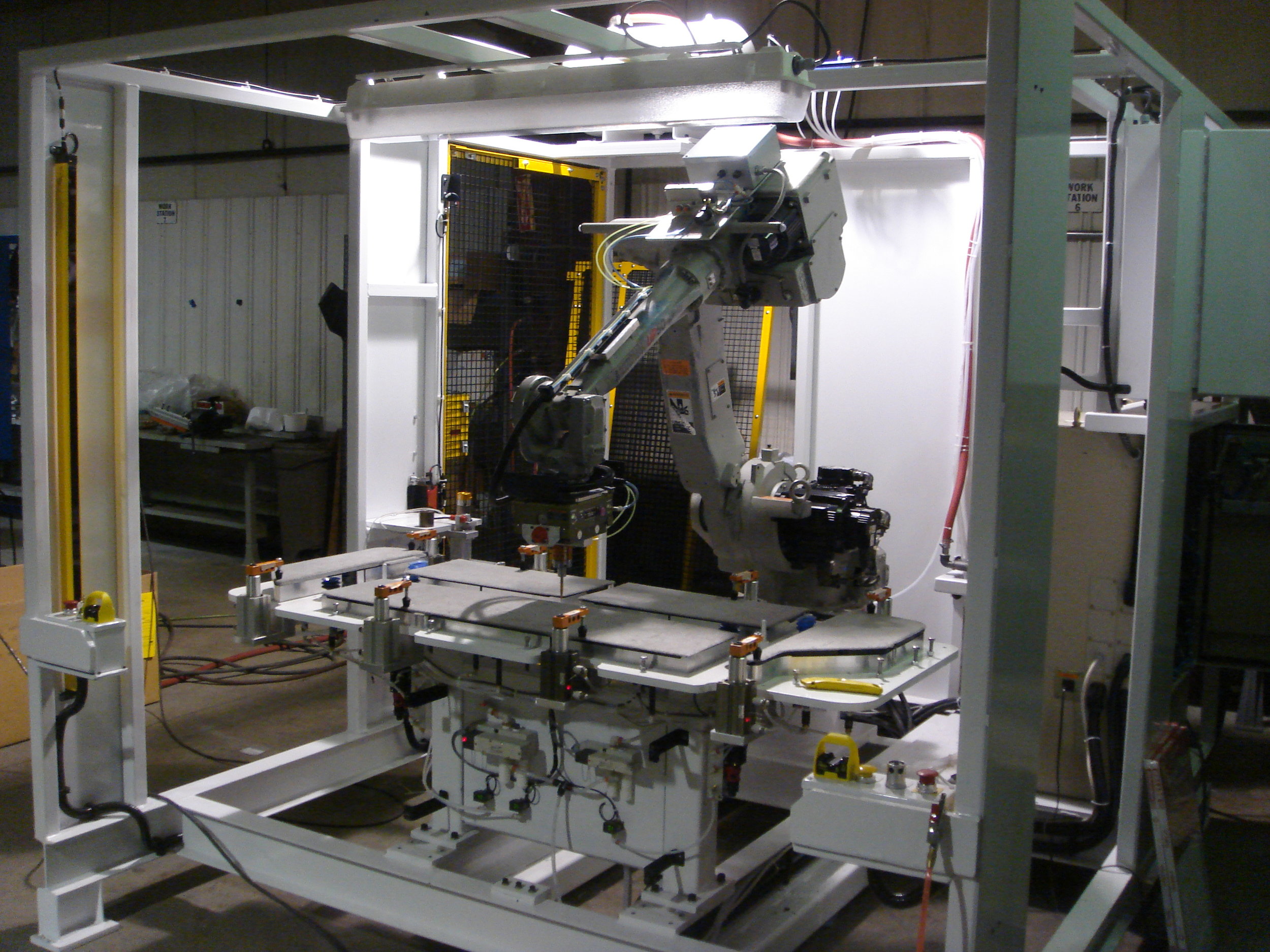

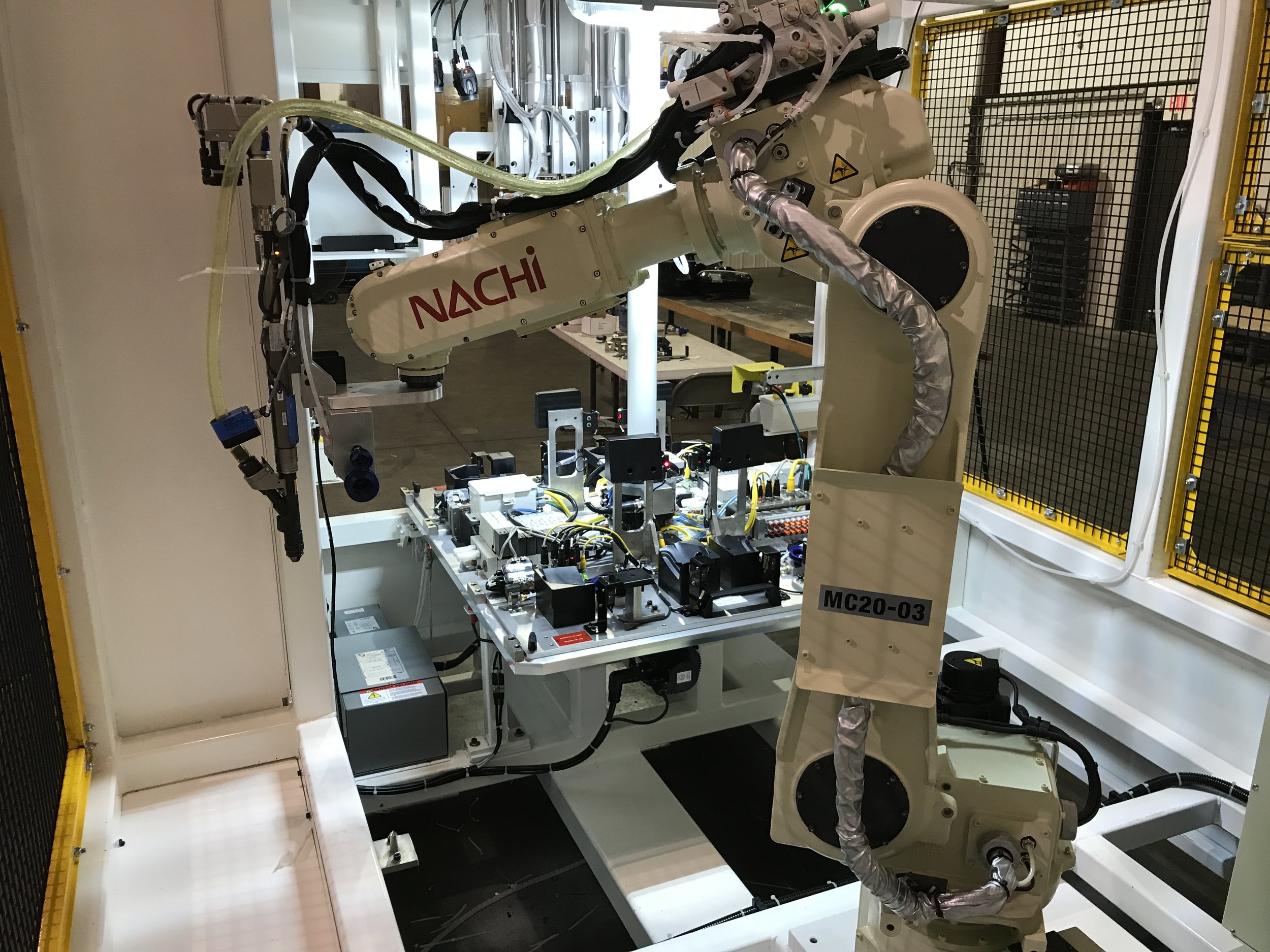

ROBOTIC MACHINE CENTERS

A universal type of robot cell implementing tool changers to swap out end-of-arm tooling so that parts may be drilled, routed, welded, etc. Typically the end user supplies the nesting for their parts that gets mounted to the base plate in the machine center.

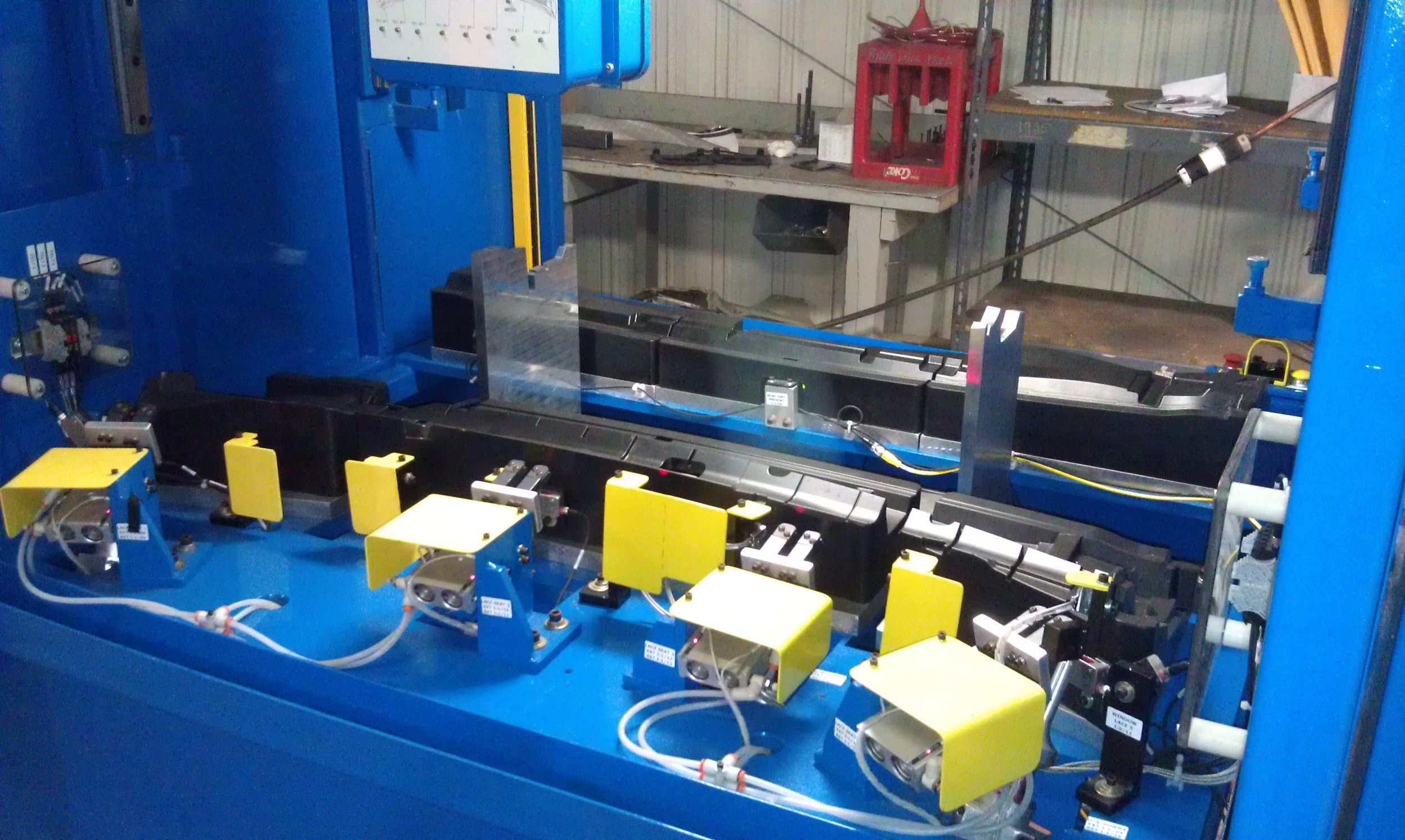

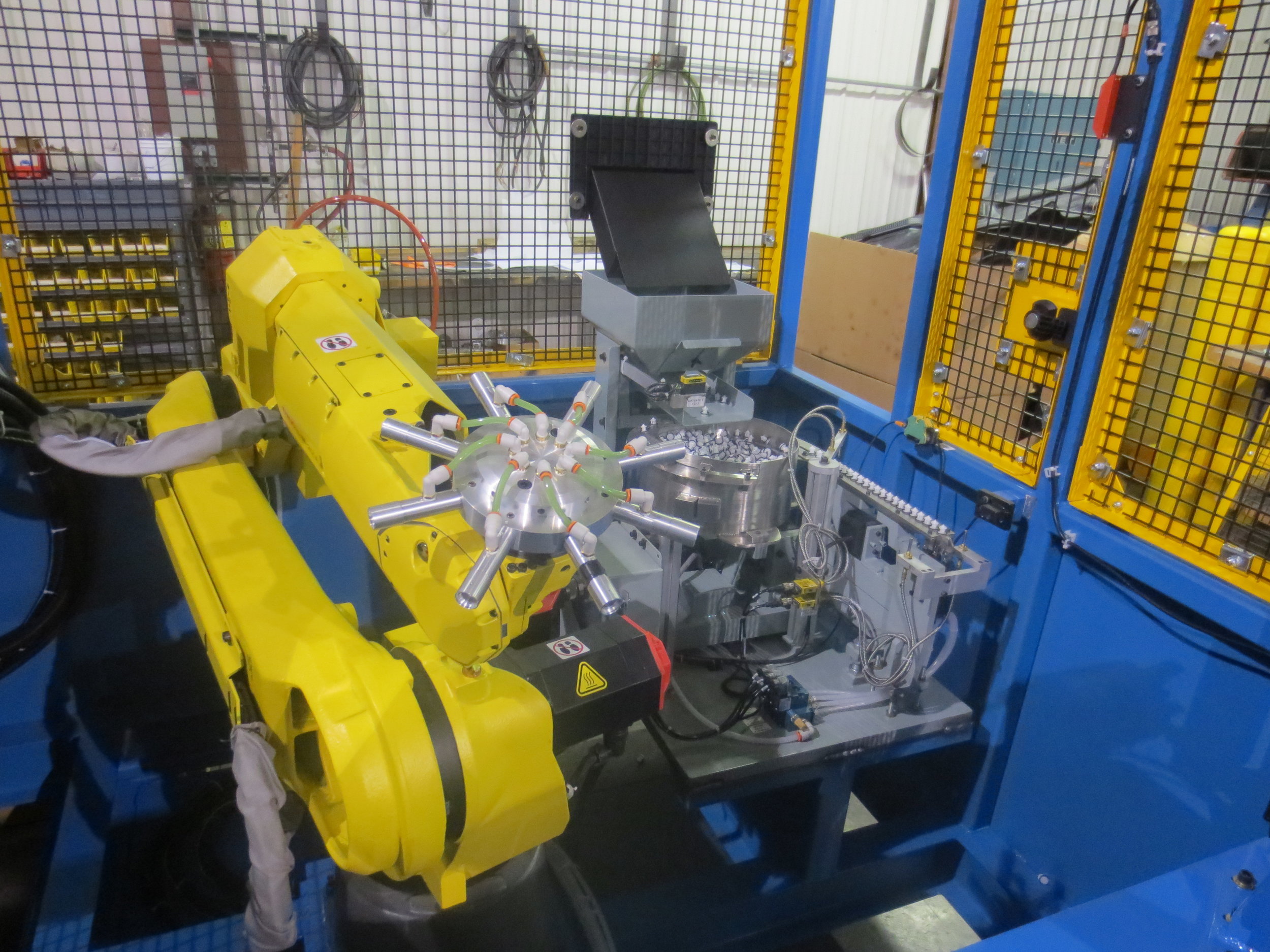

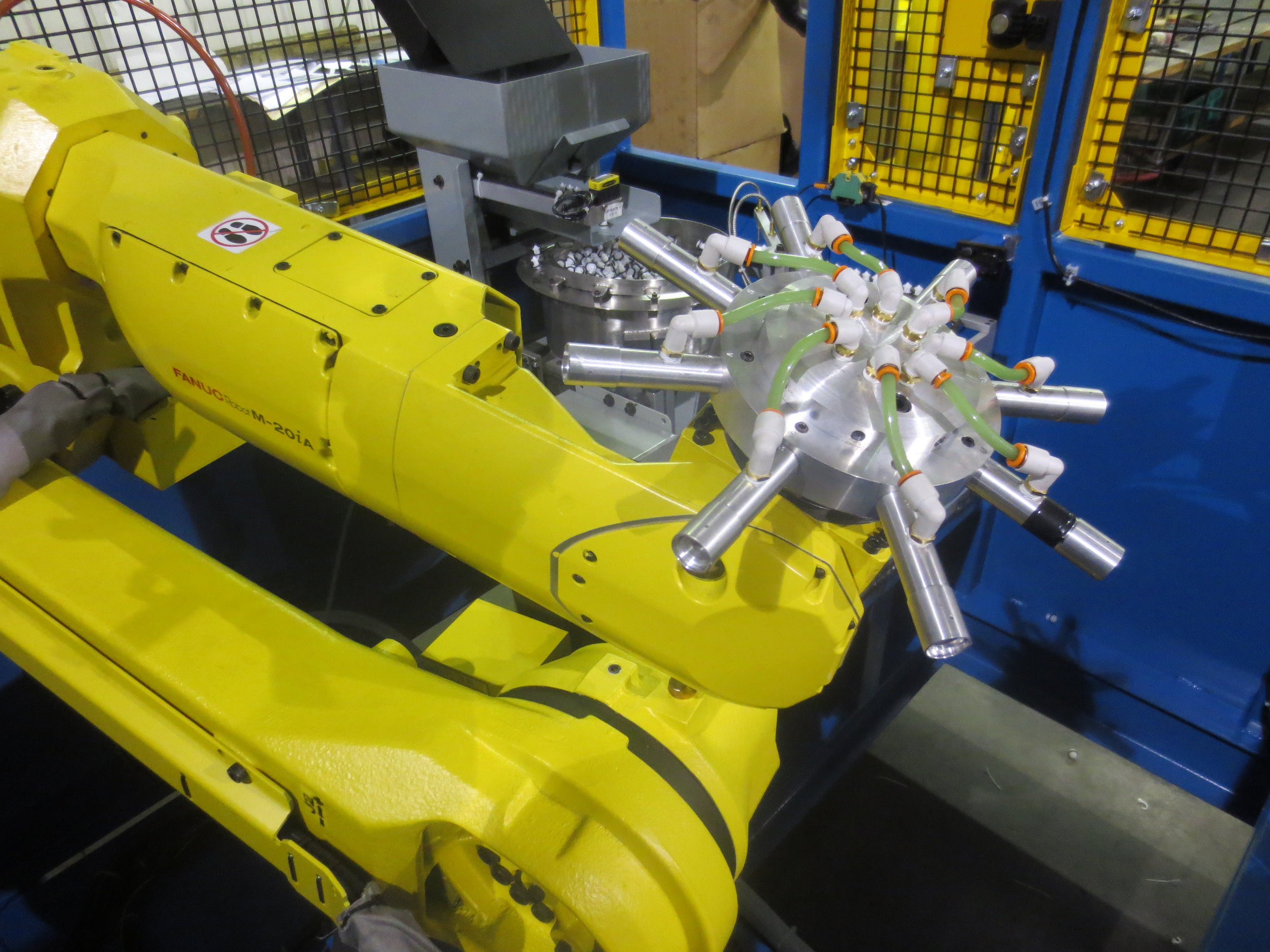

ROBOTIC SCREW DRIVING

We incorporate various manufacturers of screw driving systems that automatically feed screws to the tip of the screwdriver, which is mounted on the robot’s end-of-arm. Robots allow for very precise positioning and angling of screwdrivers to the parts being assembled, not to mention alleviating operators of any fatigue related to screw driving.